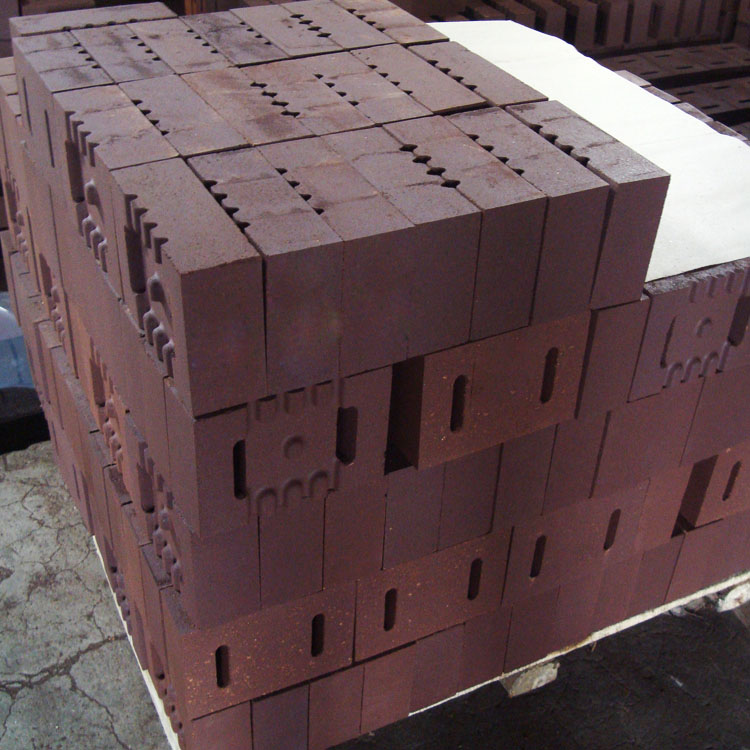

This article delves into the application advantages of the corrosion-resistant common magnesium chromium bricks introduced by Zhengzhou Tianyang Refractory Material Co., Ltd. in high-temperature chemical reactors. By elaborating on the silicate bonding process using sintered magnesia and refractory-grade chromite ore, it highlights the bricks' corrosion resistance, erosion resistance, slag resistance, and thermal shock performance under extreme working conditions.

The manufacturing process of these magnesium chromium bricks is a key factor contributing to their excellent performance. The silicate bonding technology between sintered magnesia and refractory-grade chromite ore ensures both the corrosion resistance and thermal shock stability of the bricks. This advanced technology has been proven through numerous experiments and real-world applications. For example, in some high-temperature chemical reactors with a temperature range of 1500 - 1800°C, these bricks can maintain their structural integrity for more than 2 years, while traditional magnesium bricks may need to be replaced within 1 year.

When comparing with traditional magnesium bricks, the common magnesium chromium bricks from Zhengzhou Tianyang show significant improvements. In terms of corrosion resistance, they can withstand 30% more corrosive substances, such as acidic or alkaline slags. The high-temperature strength is also enhanced. At a high temperature of 1600°C, the compressive strength of these bricks is 20% higher than that of traditional magnesium bricks, and the anti - slag performance is even more remarkable. They can reduce the slag penetration depth by up to 50%.

The technical mechanism behind their ability to cope with extreme conditions lies in the special chemical composition and structure formed by the silicate bonding. The combination of magnesia and chromite ore creates a dense structure that can effectively prevent the penetration of corrosive substances and withstand temperature fluctuations and instantaneous impacts.

The common magnesium chromium bricks have achieved wide recognition in multiple international markets, including Southern Europe, Northern Europe, Central America, Southeast Asia, and the Middle East. In Southern Europe, a chemical plant has reported a 25% reduction in maintenance costs after using these bricks in their high-temperature reactors. In Southeast Asia, the consumption of refractory materials in some industries has decreased by 20% due to the long - service life of these bricks.

These real - world cases demonstrate the market competitiveness and user acceptance of the product. The data from different regions also provides strong evidence for the product's performance and reliability.

Zhengzhou Tianyang adopts a market strategy of "combining industry and trade, technology and trade, and export." Their well - established supply chain ensures the stable supply of products. With advanced production equipment and a professional R & D team, they can quickly respond to customer demand. The after - sales service team also provides timely technical support and solutions to any problems that customers may encounter during the use of the products.

Choosing Tianyang Refractory Material means getting reliable products and professional services. Whether you are a procurement decision - maker or a technical professional, you can trust our products to meet your needs in high - temperature chemical reactors.

Ready to enhance the performance of your high - temperature chemical reactors? Click here to learn more about our corrosion - resistant common magnesium chromium bricks!