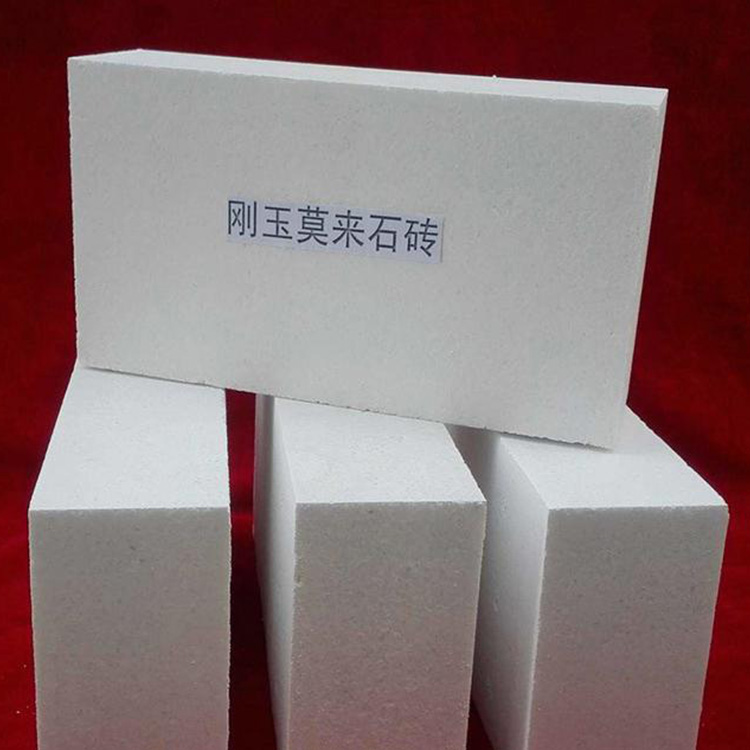

In the high - temperature ceramic firing process, the thermal conduction matching of trays plays a crucial role in ensuring the quality of ceramic products. This article focuses on the composite corundum mullite trays, which are widely used in high - temperature ceramic firing kilns, and delves into their thermal conduction matching strategies and the key role of tray structure design in controlling ceramic product deformation.

The geometric shape of the composite corundum mullite tray has a significant impact on heat distribution. For example, the design of grooves on the tray surface can effectively change the heat flow path. Through research, it has been found that a well - designed groove layout can increase the heat transfer area by about 20% - 30%, promoting more uniform heat distribution. In addition, the thickness gradient design of the tray is also an important factor. By gradually changing the thickness of the tray from the center to the edge, the heat conduction speed can be adjusted, reducing the temperature difference between different parts of the ceramic product during the firing process. In practical production, this design can reduce the temperature difference within the ceramic product by about 10 - 15 degrees Celsius, which is very beneficial for controlling deformation.

The installation method of the tray, including the stacking spacing and positioning hole design, also affects the thermal conduction efficiency and the stability of the ceramic products during firing. An appropriate stacking spacing can ensure good air circulation between trays, which helps to balance the temperature in the kiln. Generally, a stacking spacing of 3 - 5 cm can achieve better results. The design of positioning holes can ensure the accurate installation of trays, making the heat transfer between trays and the kiln car more stable. In some production lines, after optimizing the positioning hole design, the stability of the tray installation has been improved by about 30%, and the heat conduction efficiency has also been increased by about 15%.

Let's take a ceramic production enterprise as an example. Before using the optimized composite corundum mullite trays, the deformation rate of their ceramic products was as high as 15%. After adopting the new tray structure design and installation method, the deformation rate dropped to about 5%. This significant improvement is mainly due to the more uniform heat distribution and better stability during the firing process. The following table shows the comparison of production data before and after the improvement:

| Indicator | Before Improvement | After Improvement |

|---|---|---|

| Deformation Rate | 15% | 5% |

| Production Efficiency | 80 pieces per day | 100 pieces per day |

Front - line technicians have accumulated a wealth of on - site detection and parameter debugging experience. They use infrared thermometers to measure the surface temperature of trays and ceramic products in real - time, and adjust the firing parameters according to the temperature distribution. For example, if the temperature difference between the center and the edge of the ceramic product is too large, they will adjust the heating rate or the air circulation in the kiln. Through these on - site detection and debugging methods, the quality of ceramic products can be further improved.

In conclusion, the composite corundum mullite tray, with its unique structure design and excellent thermal conduction performance, can effectively control the deformation of ceramic products during the high - temperature firing process, improve the yield rate, and enhance production efficiency. If you are looking for a high - quality tray solution for your ceramic production, don't miss our composite corundum mullite trays. Click here to learn more and start your procurement now!