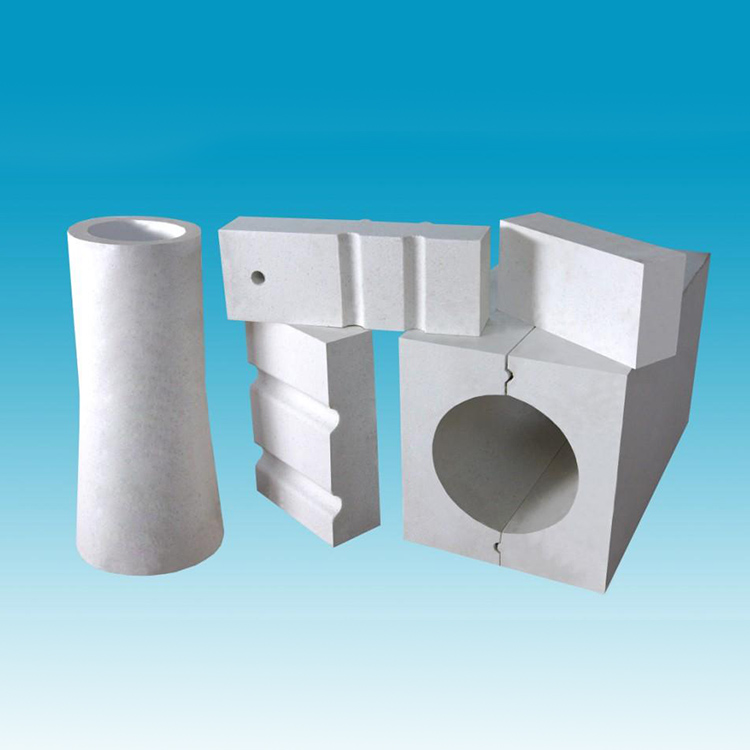

As a technical professional responsible for ceramic kiln operations, you are well aware that improper tray selection can critically impact product quality—leading to warping, collapse, or even costly batch failures. This article dives deep into the performance parameters of composite corundum-mullite trays, focusing on thermal expansion coefficients, thermal shock resistance, wear durability, and chemical stability, to empower you with actionable insights for optimizing your kiln processes.

The kiln tray serves as the physical foundation for ceramic products during high-temperature firing, and its material properties directly correlate to product integrity and yield. Key metrics to consider include:

| Property | Traditional Alumina Tray | Composite Corundum-Mullite Tray |

|---|---|---|

| Thermal Expansion Coefficient (10^-6 /°C) | 7.5 – 8.0 | 4.5 – 5.5 |

| Thermal Shock Resistance | Moderate | High (can withstand ΔT > 200°C) |

| Wear Resistance | Average | Excellent (50%+ longer lifespan) |

| Chemical Stability | Prone to glaze corrosion | Resistant under typical kiln atmospheres |

Different ceramic products impose specific demands on kiln trays. Understanding these nuances helps you avoid common quality pitfalls:

Selecting composite corundum-mullite trays provides a strategic advantage across these scenarios, balancing thermal compatibility and durability.

Operating temperature decisively influences tray degradation rate. Below is a practical guide to lifespan management within key temperature intervals you typically work with:

| Temperature Range | Risk Factors | Maintenance Strategies | Expected Tray Lifespan (Cycles) |

|---|---|---|---|

| 1000°C - 1100°C | Minimal thermal stress, surface wear | Routine inspection, cleaning every 50 cycles | ~500 |

| 1100°C - 1250°C | Moderate thermal expansion, early microcracking | Non-destructive testing every 100 cycles | ~300 |

| 1250°C - 1400°C | Severe thermal shock, accelerated wear | Limit rapid cooling; replace after 150-200 cycles | ~150 |

Your tray’s health check: Have you noticed any of these signs lately?

"Switching to composite corundum-mullite trays transformed our production. The enhanced thermal shock resistance slashed tray breakage by 40%, and decreased the occurrence of ceramic warpage. The overall firing yield improved from 85% to 95% within 6 months." — Industry Expert, Ceramic Manufacturing Leader

Incorporate these trays in your firing schedule, combining vigilant lifecycle monitoring and proactive maintenance, to unlock improved durability and product quality.

Interested in mastering ceramic kiln tray selection and lifespan strategies?

Download Your Comprehensive Ceramic Tray Selection Whitepaper

Or join our Technical Discussion Group for peer support and expert guidance.