In industrial kiln heat treatment, the selection and operation of kiln furniture directly impact production efficiency and product quality. This article delves into the differential usage strategies of kiln furniture within the 1000°C–1300°C range. By analyzing real - world cases, we'll explain how to extend the lifespan of kiln furniture and reduce the risk of thermal shock damage through proper installation, temperature control management, crack monitoring, and repair.

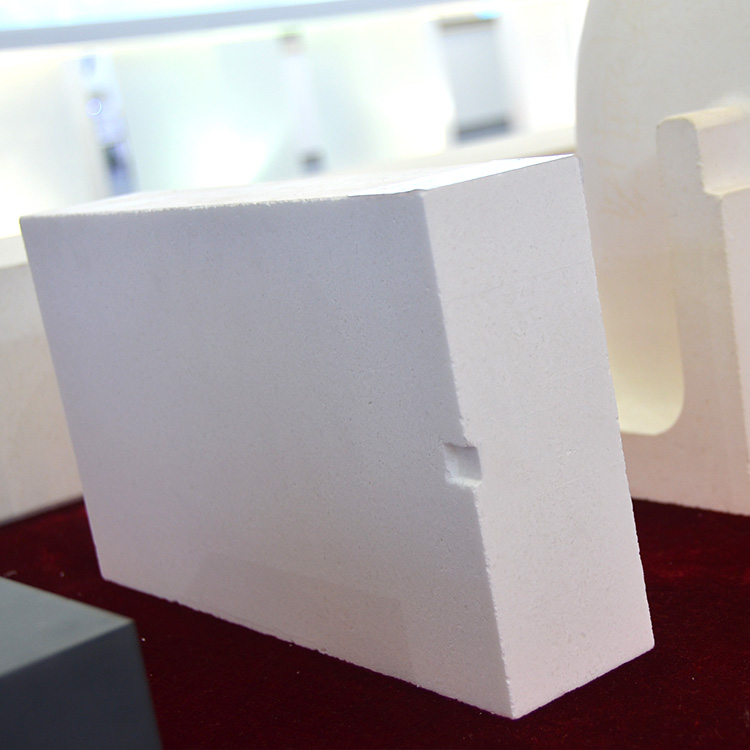

Starting with the installation points of high - temperature kiln furniture, the design of thermal expansion compensation and the rationality of layout are crucial for reducing mechanical stress. For example, a well - designed expansion compensation can reduce mechanical stress by up to 30%, which significantly prolongs the service life of kiln furniture. As shown in Figure 1, a reasonable layout can ensure uniform heat distribution, minimizing the impact of uneven heating on kiln furniture.

Different firing temperature ranges have distinct performance differences in kiln furniture. In the 1000°C - 1100°C range, materials like cordierite kiln furniture, such as the ones from Zhengzhou Tianyang Sunrise, offer good thermal shock resistance. However, as the temperature rises to 1200°C - 1300°C, some high - alumina materials may be more suitable due to their higher melting points. Table 1 below shows the performance characteristics and limitations of different materials in various temperature ranges:

| Temperature Range (°C) | Suitable Materials | Characteristics | Limitations |

|---|---|---|---|

| 1000 - 1100 | Cordierite | Good thermal shock resistance | Lower melting point |

| 1100 - 1200 | Cordierite - mullite | Balanced performance | Limited high - temperature strength |

| 1200 - 1300 | High - alumina | High melting point, good high - temperature strength | Poor thermal shock resistance |

In scenarios of rapid heating or cooling, controlling the temperature change rate is essential. For example, in a rapid heating process, a temperature rise rate of no more than 10°C/min can effectively reduce the risk of thermal shock damage. Figure 2 shows the comparison of the service life of kiln furniture under different temperature change rates.

Regular inspection is necessary to identify potential crack hazards. Visual inspection combined with simple tools can detect early - stage cracks. Once cracks are found, appropriate repair techniques should be applied. For small cracks, some special repair materials can be used, which can restore the performance of kiln furniture to a certain extent. As shown in Figure 3, after crack repair, the service life of kiln furniture can be extended by about 20%.

Establishing a systematic maintenance system is of great value. It can enhance the safety and continuity of kiln operation. By following a scientific maintenance plan, enterprises can avoid unexpected downtime and reduce production losses.

If you're looking for high - quality kiln furniture solutions, consider Zhengzhou Tianyang Sunrise cordierite kiln furniture. It offers reliable performance and can be a great choice for optimizing your heat treatment processes. Click here to learn more about how to improve the stability of your kiln furniture and achieve cost - effective operation!