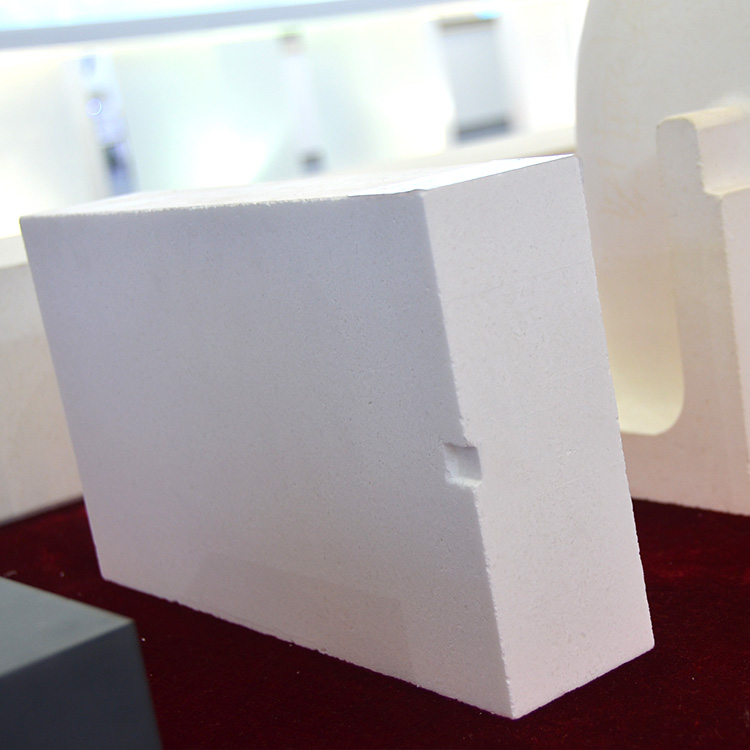

Composite corundum-mullite sintering trays are integral components in the high-temperature sintering of magnetic materials, demanding rigorous performance standards such as high purity, low porosity, and excellent thermal conductivity. These trays must withstand thermal cycles in high-temperature reducing atmospheres, preserving their structural integrity while preventing metallic contamination. However, thermal stress-induced cracking remains a critical bottleneck affecting product quality and yield.

During sintering processes, temperature gradients within the composite corundum-mullite trays generate internal stresses that can surpass the material's fracture toughness. Typical manifestations of thermal stress cracking include surface and subsurface microcracks, which compromise mechanical strength and promote defect formation in the overlaid magnetic materials. Additionally, oxidative degradation can exacerbate surface damage, diminishing tray lifespan and increasing contamination risk.

The high-temperature (typically 1200–1400°C) reducing atmosphere essential for magnetic material sintering poses multifaceted challenges. Firstly, the chemical stability of tray materials under these conditions is critical to avoid phase transformations and microstructural degradation. Secondly, potential infiltration of metallic vapors can lead to contamination, jeopardizing magnetic properties. The composite nature of corundum and mullite fibers, while optimal for thermal expansion control, can also encode sites for crack nucleation under fluctuating thermal stresses.

Microcracks in sintering trays often serve as nucleation sites for inclusions within magnetic materials, deteriorating their magnetic and mechanical characteristics. These inclusions arise from fragmented tray material or trapped debris formed as cracks propagate during thermal cycling. Preventing microcrack formation is thus directly correlated with minimizing magnetic material defects, a critical quality control metric.

| Issue | Proposed Solution | Expected Benefit |

|---|---|---|

| Thermal Stress Generation | Optimize furnace heating/cooling rates; implement thermal gradient minimization through insulation design | Reduced crack initiation; enhanced tray lifespan by 15-20% |

| Material Phase Instability | Utilize high-density composite fabrication targeting porosity < 10%; select additives to stabilize mullite phases at 1400°C | Increased chemical stability under reducing atmosphere; minimized microcracks |

| Metallic Contamination Risk | Apply anti-contamination coatings and surface treatments; maintain furnace atmosphere purity | Improved magnetic material purity; defect rate reduction by up to 10% |

| Crack Repair & Prevention | Regular tray inspection with microscopic imaging; timely grinding and sealing of minor cracks | Prolonged tray service life and stable production quality |

To fully exploit the composite corundum-mullite tray's potential, production facilities should adopt precise thermal cycling protocols. A controlled temperature ramp rate below 5°C/min in critical phases reduces internal stresses drastically. Concurrently, maintaining a consistent high-purity reducing atmosphere (typically hydrogen-nitrogen mix at 5-20% hydrogen) prevents oxidative damage while minimizing metal contamination sources.

Emphasis on regular microscopic inspections enables early detection of incipient cracks, facilitating timely intervention before defect propagation. Integrating these inspections with furnace operation data promotes predictive maintenance and process optimization.

For tailored composite corundum-mullite sintering trays engineered to withstand the rigors of high-temperature reducing environments and minimize thermal stress cracking, contact our technical support team today to explore customized solutions designed to elevate your sintering process efficiency and product quality.