In the demanding landscape of magnetic material sintering — particularly for permanent ferrite and NdFeB magnets — the selection of kiln trays is pivotal to ensuring process stability and product quality. This article explores the performance of composite corundum-mullite trays under high-temperature reducing atmospheres, providing data-backed insights and pragmatic process recommendations. Such insights serve as valuable guidance for sintering engineers committed to optimizing yield and mitigating common defects.

Sintering magnetic materials demands strict control of the kiln atmosphere—commonly a high-temperature reducing environment—to prevent oxidation and maintain magnetic properties. However, these conditions impose severe thermal and chemical stresses on kiln trays, potentially compromising their structural integrity and surface chemistry. Major issues encountered include:

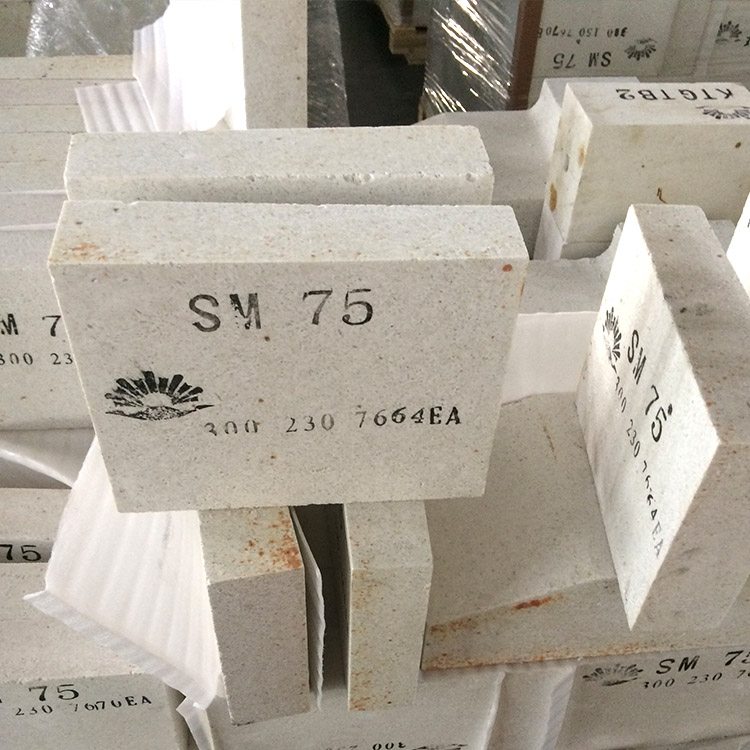

The composite corundum-mullite composition, engineered to combine the thermal shock resistance of mullite with corundum's mechanical strength and chemical inertness, has become the material of choice for sintering trays in these environments. Empirical testing under typical sintering gradients (up to 1400°C) reveals:

| Property | Measured Value | Industry Benchmark |

|---|---|---|

| Thermal Shock Resistance (cycles) | > 25 cycles | > 15 cycles |

| Metal Contamination Threshold (ppm Fe) | < 5 ppm | < 10 ppm |

| Porosity (%) | 10 - 12 % | 8 - 15 % |

| Microcrack Incidence Rate | < 3% | < 5% |

Table 1 – Key performance metrics of composite corundum-mullite trays under controlled sintering conditions.

Detailed examination of trays post 50 sintering cycles under reducing atmospheres uncovered the following failure phenomena alongside their origins:

For enhanced tray longevity and improved sintered magnet quality, adopting the following process adjustments is advised:

An industrial partner reported frequent tray cracking after 30 sintering cycles, significantly impacting yield. Through on-site inspection and temperature curve data analysis, it was identified that rapid temperature cycling and inconsistent gas control caused thermal stress-induced fractures. Following implementation of the above recommendations, cracking incidence dropped by 65% within two months, enabling a 15% productivity increase.

Seasoned sintering professionals emphasize meticulous atmospheric control and gradual thermal ramping as cornerstones for tray stability. Additionally, integrating real-time temperature and atmosphere sensors in kiln operations is highly recommended to prevent deviations that may induce tray failure.

"Composite corundum-mullite trays engineered according to ISO 13717 standards exhibit superior performance in reducing atmospheres, with documented low metal contamination vital for magnetic properties retention." — Customer Feedback, Major NdFeB Sintering Plant.

Unlock tailored process optimization to enhance your magnetic material sintering success.