Common Mistakes and Practical Tips for Installing Corrosion-Resistant Fire Bricks in High-Temperature Reactors

27 01,2026

Tutorial Guide

This article offers an in-depth analysis of corrosion-resistant refractory materials used for lining high-temperature chemical reactors, with a focus on common magnesia-chrome bricks. It highlights their exceptional thermal shock resistance, erosion durability, and slag resistance under extreme conditions. By addressing frequent installation errors encountered during reactor maintenance and operation, the article provides practical guidance and case studies to enhance installation efficiency and extend equipment lifespan. Through scientific evaluation and application best practices, users will gain a comprehensive understanding of key factors in reactor lining installation to ensure safe, stable operation and cost-effective maintenance.

Common Pitfalls in Refractory Brick Installation & Practical Tips to Boost High-Temperature Reactor Lining Efficiency

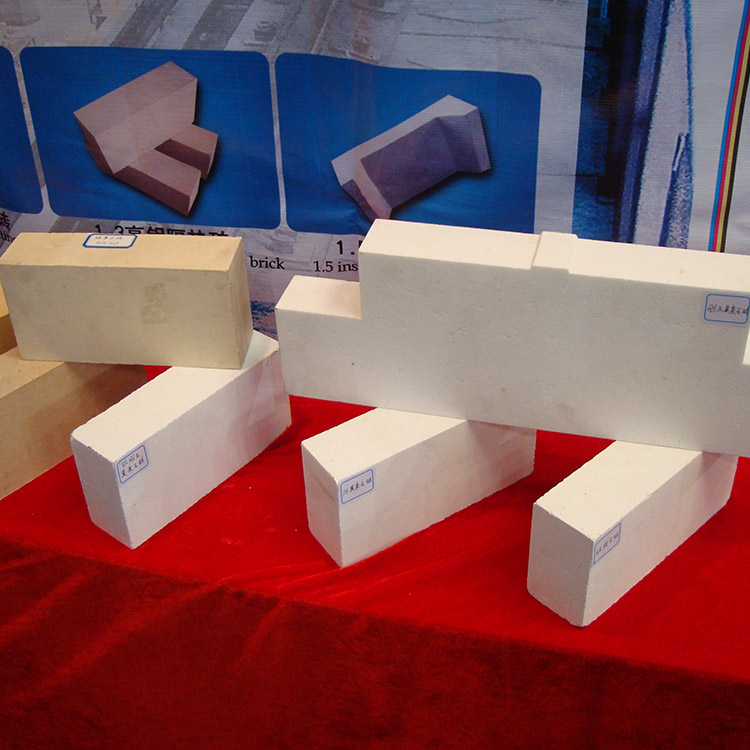

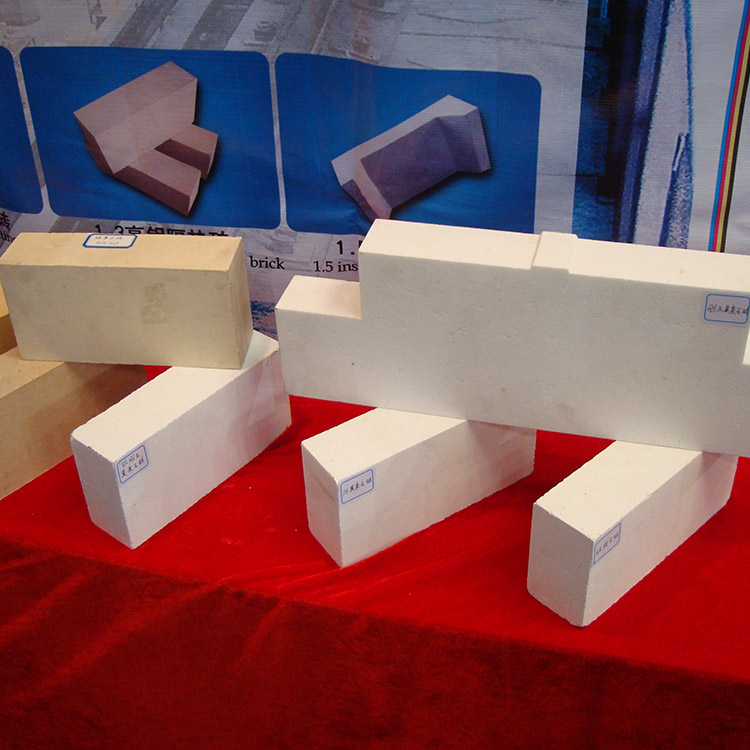

When it comes to high-temperature chemical reactors, selecting and installing the optimal refractory lining is crucial for maintaining equipment integrity and operational efficiency. Ordinary magnesia-chrome bricks with advanced corrosion resistance have emerged as a proven choice, offering remarkable thermal shock stability, erosion resistance, and slag resistance under extreme working conditions.

Why Choose Corrosion-Resistant Magnesia-Chrome Bricks for Reactor Linings?

Ordinary magnesia-chrome bricks combine chemical durability with robust physical properties that effectively handle the multifaceted challenges of chemical reactors operating above 1300°C. Their unique composition provides:

- Exceptional Thermal Shock Resistance: Withstand rapid temperature fluctuations reducing crack formation risk by over 30% compared to traditional magnesia bricks.

- Superior Corrosion Resistance: Resist aggressive chemical attack from molten slags and alkalis typical in high-temperature chemical processes, extending lining lifespan by up to 25%.

- Enhanced Slag Resistance: Minimize slag adhesion that compromises heat transfer and accelerates wear, ensuring steady reactor performance.

Selecting these bricks translates directly into lower maintenance frequency and downtime, improving your plant’s operational continuity and cost-effectiveness.

Identifying and Avoiding Installation Mistakes: Lessons from Practical Cases

Despite the superior material properties, improper installation can critically undermine the refractory lining’s performance. Common pitfalls include:

- Insufficient Surface Preparation: Residual dust or moisture can prevent proper brick adhesion, causing early debonding and cracks.

- Incorrect Joint Filling: Uneven or overly thin joints lead to stress concentration and subsequent lining failure.

- Poor Alignment and Fixing: Misaligned bricks reduce mechanical interlocking, impairing structural stability under thermal cycling.

Case studies reveal that addressing these factors during installation can enhance lining service life by 15-20%. For example, a major petrochemical plant reduced downtime by 30% after implementing a standardized surface prep and joint treatment protocol.

Key Practical Tips for Effective Installation

To help you avoid common missteps and optimize your refractory installation, consider these actionable recommendations:

- Thoroughly Clean and Dry Surface: Remove all dust, oil residues, and moisture before brick laying to ensure strong adhesive bonding.

- Use High-Quality Mortar Suitable for Magnesia-Chrome Bricks: Consistent joint thickness of 3-5 mm prevents stress concentration.

- Employ Precision Alignment Tools: Maintain uniform brick placement to distribute thermal stresses evenly.

- Implement Stepwise Heating During Commissioning: Gradually ramp up temperature to reduce thermal shock at start-up.

Assessing Thermal Shock and Slag Resistance: Modern Testing Approaches

Quantifying thermal shock stability and slag resistance is key to selecting the right refractory material. Industry-standard assessment methods include:

- Thermal Shock Testing: Repeated rapid temperature cycling (e.g. 1600°C down to ambient water quench) while monitoring crack initiation and propagation. Corrosion-resistant magnesia-chrome bricks show 40% fewer cracks than traditional magnesia bricks under identical conditions.

- Slag Resistance Evaluation: Exposure to synthetic slag melts simulating plant slags, with visual and mechanical integrity assessments post-test.

These objective measures correlate strongly with field performance, giving you confidence in material selection tailored to your unique application conditions.

Integrating Technology and Application Know-How for Optimal Outcomes

Successful refractory lining projects rely on merging material science with hands-on application expertise. Leveraging digital modeling to predict thermal stress zones and bespoke installation training ensures your team can maximize lining durability.

Furthermore, ongoing condition monitoring—using infrared thermography and acoustic emission sensors—alerts you to early deterioration, enabling proactive maintenance before costly failures occur.