When your ceramic products consistently suffer from warping, collapsing, or surface flaws after high-temperature firing, the root cause may not lie within the greenware but rather in the kiln shelf material you choose. Understanding how the right tray substrate impacts firing stability is critical to elevating production efficiency and product quality.

Kiln shelves must withstand intense thermal stress, abrasive wear, and chemical exposure without compromising their integrity. This supports consistent heat transfer and preserves the shape and surface of ceramic pieces throughout firing cycles.

Key performance factors include:

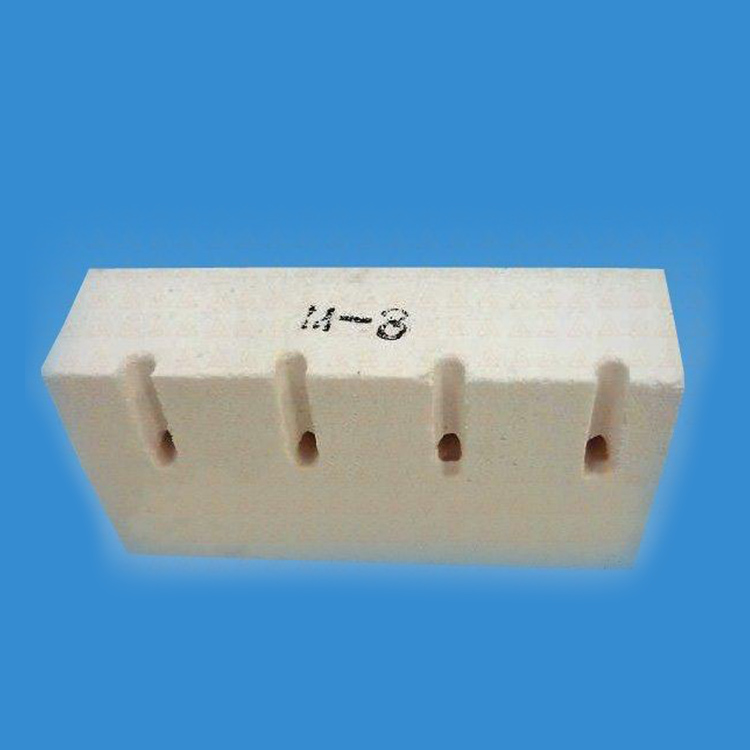

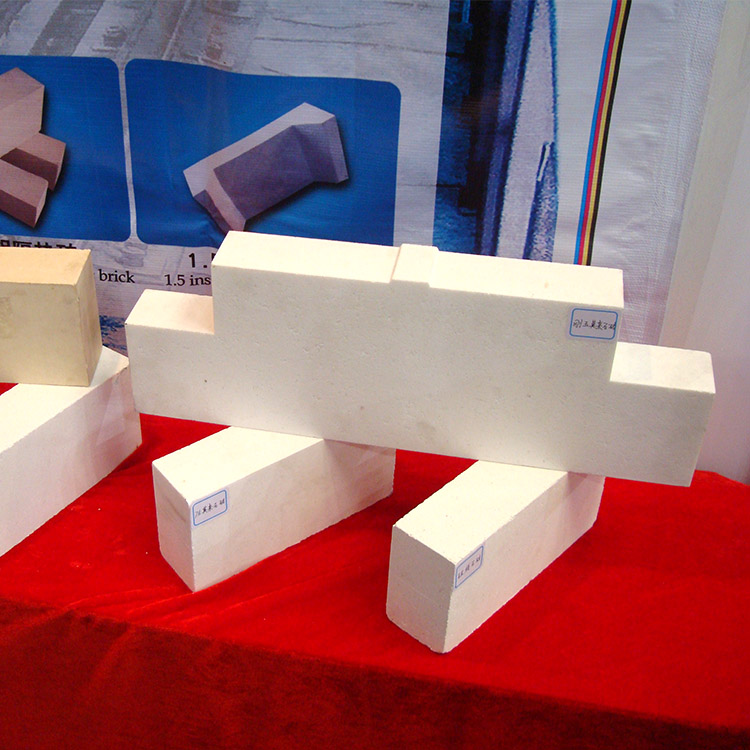

Composite corundum-mullite shelves have emerged as an advanced material outperforming traditional refractory bricks and common ceramic shelves in key areas:

| Property | Traditional Refractory Brick | Common Ceramic Shelf | Composite Corundum-Mullite Shelf |

|---|---|---|---|

| Thermal Stability | Moderate deformation risk above 1200°C | Prone to surface spalling and warping | Maintains shape with minimal expansion up to 1400°C |

| Thermal Shock Resistance | Relatively low, risk of cracking on fast cooling | Low resistance, fragile | High tolerance to rapid temperature changes |

| Wear Resistance | Easily worn in high contact areas | Surface easily scratched | Excellent abrasion resistance |

| Chemical Inertness | Susceptible to flux attack | Moderate resistance | Highly resistant to chemical corrosion |

Each ceramic product category applies unique stresses on kiln shelves, making it essential to select materials aligned with operational demands:

Mosaic tile firing demands stable heat distribution to prevent warping of thin, intricate shapes. Composite corundum-mullite shelves offer superior thermal shock resistance that minimizes cracking, thereby reducing batch rejects.

Firing sanitaryware requires shelves with excellent load-bearing capacity and chemical inertness to endure high firing temperatures (up to 1400°C) and exposure to glazing agents. The advanced shelf material prevents contamination and extends service life.

Roofing tile production involves repetitive thermal cycling and heavy product weight, demanding shelves with outstanding wear resistance and minimal thermal expansion to avoid deformation and surface defects.

Understanding how kiln shelves age across different temperature ranges enhances preventive maintenance strategies:

Best practices include keeping detailed usage logs, applying non-destructive ultrasonic tests, and scheduling timely shelf replacements to prevent sudden failures that impact production.

Decision-making backed by these technical insights leads to:

Get exclusive access to detailed technical data, real-world case studies, and expert recommendations. Join our professional technical community to stay ahead in ceramic firing optimization.