In the ceramic manufacturing industry, the issue of deformation during the firing process has long been a headache for producers. This problem not only reduces the yield of finished products but also increases production costs. In this article, we will explore how the composite corundum mullite tray can effectively control ceramic firing deformation through structural design optimization, and share on - site detection and debugging techniques used by front - line technicians.

Ceramic products often experience various degrees of deformation during firing. One of the main reasons is the uneven heating of the trays. When the heat distribution on the tray is not uniform, different parts of the ceramic products will expand or contract at different rates, leading to deformation. For example, in some traditional ceramic firing processes, the deformation rate can reach up to 20% due to uneven heating.

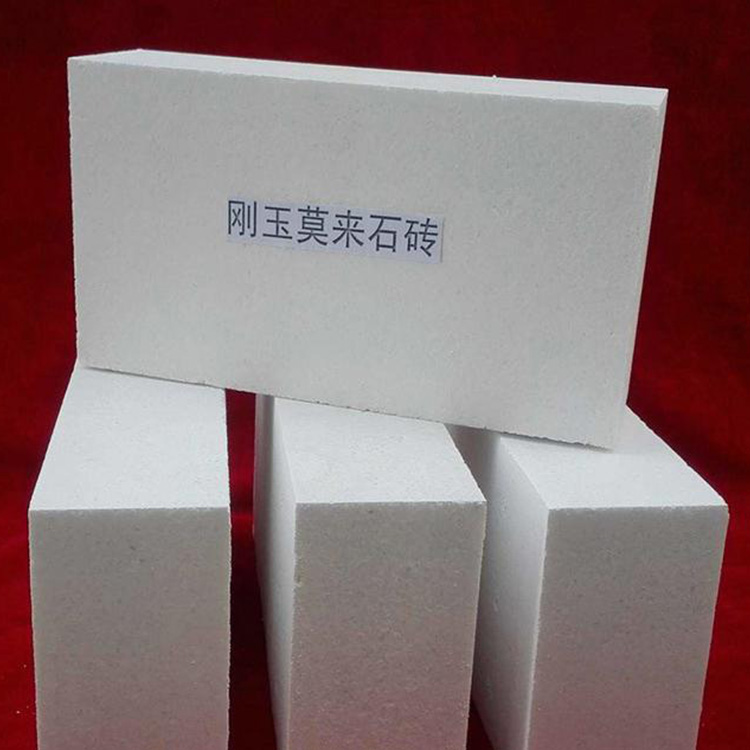

The composite corundum mullite tray is made of high - quality materials with excellent thermal stability, high strength, and good thermal shock resistance. It is suitable for a wide range of ceramic firing processes, especially for high - temperature firing. Its material properties ensure that it can maintain stable performance under high - temperature conditions, providing a reliable support for ceramic products during firing.

The geometric shape of the composite corundum mullite tray, including groove distribution and thickness gradient, has a significant impact on heat conduction uniformity. By designing reasonable groove distributions, the heat can be more evenly transferred to the ceramic products. For example, a well - designed groove can increase the heat transfer area by about 15%, improving the heat conduction efficiency. The thickness gradient design can also adjust the heat transfer rate in different parts of the tray, ensuring that the ceramic products are heated evenly.

The installation method of the tray, such as stacking spacing adjustment and positioning hole design, also plays an important role in promoting heat conduction. Adjusting the stacking spacing can ensure proper air circulation between trays, which is beneficial for heat transfer. For instance, when the stacking spacing is increased by 1 cm, the heat transfer efficiency can be improved by about 10%. The reasonable design of positioning holes can ensure the accurate placement of trays, avoiding uneven heating caused by misalignment.

To ensure uniform heating, it is necessary to match the tray with the kiln car and understand the overall heat conduction mechanism. The heat transfer between the tray and the kiln car affects the temperature distribution of the ceramic products. By optimizing the matching between the two, the heat conduction efficiency can be improved, and the deformation rate can be reduced. For example, through proper matching, the deformation rate can be reduced from 20% to 5%.

| Production Line | Original Deformation Rate | Deformation Rate after Using Optimized Trays | Finished Product Yield Improvement |

|---|---|---|---|

| Line A | 18% | 3% | 15% |

| Line B | 22% | 4% | 18% |

Front - line technicians have developed a series of on - site detection and debugging techniques. These techniques can quickly identify problems in the firing process and make timely adjustments. For example, they can use infrared thermometers to detect the temperature distribution on the tray surface, and then adjust the firing parameters according to the detection results.

If you are struggling with ceramic firing deformation issues, our high - performance composite corundum mullite trays can be your ideal solution. These trays have been proven to effectively reduce deformation rates and improve product yields in real - world production. Don't miss out on this opportunity to enhance your ceramic manufacturing process. Click here to learn more about our composite corundum mullite trays.