In the realm of high-temperature industrial kiln furniture materials, cordierite porous materials are emerging as a revolutionary force, driving significant technological innovation and improvement. This article delves into the innovative applications and technological advancements of cordierite porous materials in high-temperature industrial kilns, offering valuable insights for heat treatment engineers and material researchers.

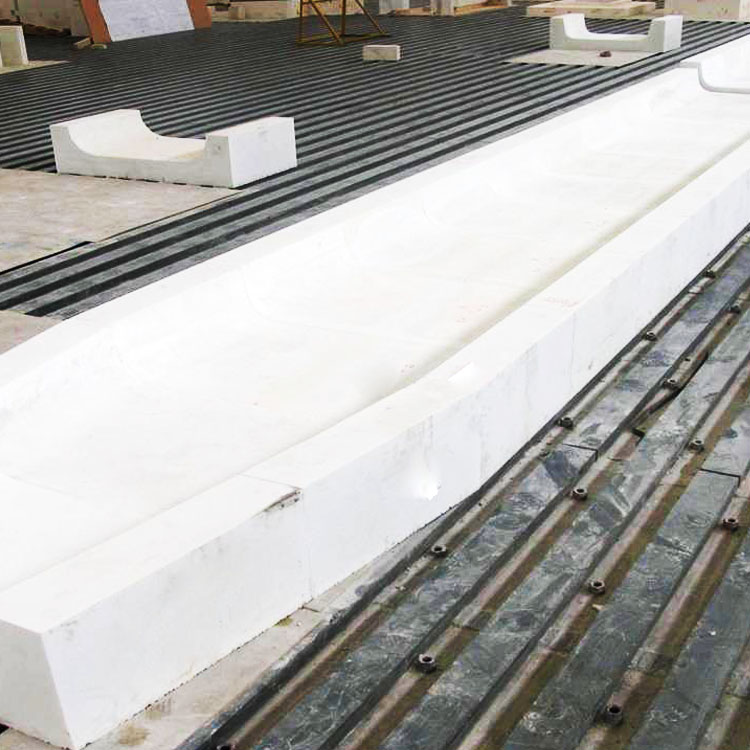

Cordierite porous materials possess a unique microstructure that contributes to their outstanding thermal properties. Microstructural analysis reveals a well - organized porous structure, which endows the material with a low density. The low density is a key advantage, as it reduces the overall weight of kiln furniture, leading to energy savings during operation. For example, compared with traditional kiln furniture materials, cordierite porous materials can reduce the weight of kiln furniture by up to 30%.

From a thermophysical perspective, cordierite porous materials exhibit a low creep rate and excellent thermal shock resistance. The creep rate, which is a measure of the material's deformation under long - term high - temperature stress, is as low as 0.1% after 100 hours at 1200°C in laboratory tests. This low creep rate ensures the dimensional stability of kiln furniture during high - temperature firing and heat treatment processes, which typically range from 1000°C to 1300°C.

The unique properties of cordierite porous materials make them highly suitable for various key kiln furniture components, such as installers, cranks, felts, and support systems. In the case of installers, the low density and high thermal shock resistance of cordierite porous materials allow for quick installation and removal during the kiln operation, reducing downtime. For example, in a ceramic manufacturing plant, the use of cordierite porous installers has reduced the installation time by 20%.

When it comes to cranks, the material's low creep rate ensures smooth and accurate movement, which is crucial for the precise control of the kiln process. In a metal heat - treatment facility, the application of cordierite porous cranks has improved the process accuracy by 15%.

For felts and support systems, the excellent thermal insulation properties of cordierite porous materials help to maintain a stable temperature environment inside the kiln. This reduces heat loss and improves energy efficiency. In a glass manufacturing plant, the use of cordierite porous support systems has led to a 10% reduction in energy consumption.

Several industry case studies demonstrate the significant benefits of cordierite porous materials. In a refractory manufacturing company, the adoption of cordierite porous kiln furniture has increased the service life of the kiln equipment by 50%. This is mainly due to the material's high - temperature resistance and low wear characteristics. At the same time, the maintenance cost has been reduced by 30% because of the material's excellent durability.

In a semiconductor manufacturing plant, the use of cordierite porous materials in the heat - treatment process has optimized the process efficiency. The precise temperature control and low thermal mass of the material have reduced the processing time by 25%, leading to a significant increase in production capacity.

Looking ahead, there are several promising directions for the improvement of cordierite porous materials. Researchers are exploring ways to further enhance the material's thermal conductivity while maintaining its low density and high thermal shock resistance. This could lead to even more efficient heat transfer in the kiln, reducing energy consumption and improving process speed.

Another area of research is the development of new manufacturing processes to produce cordierite porous materials with more uniform pore sizes and distributions. This would improve the material's mechanical properties and performance consistency.

In conclusion, cordierite porous materials offer a cost - effective solution for high - temperature industrial kiln furniture. Their unique combination of low density, excellent thermal properties, and high durability can significantly enhance equipment performance and process efficiency, while reducing maintenance costs. For heat treatment engineers and material researchers, cordierite porous materials present a wealth of opportunities for innovation. If you are interested in exploring how cordierite porous materials can benefit your business, click here to learn more.