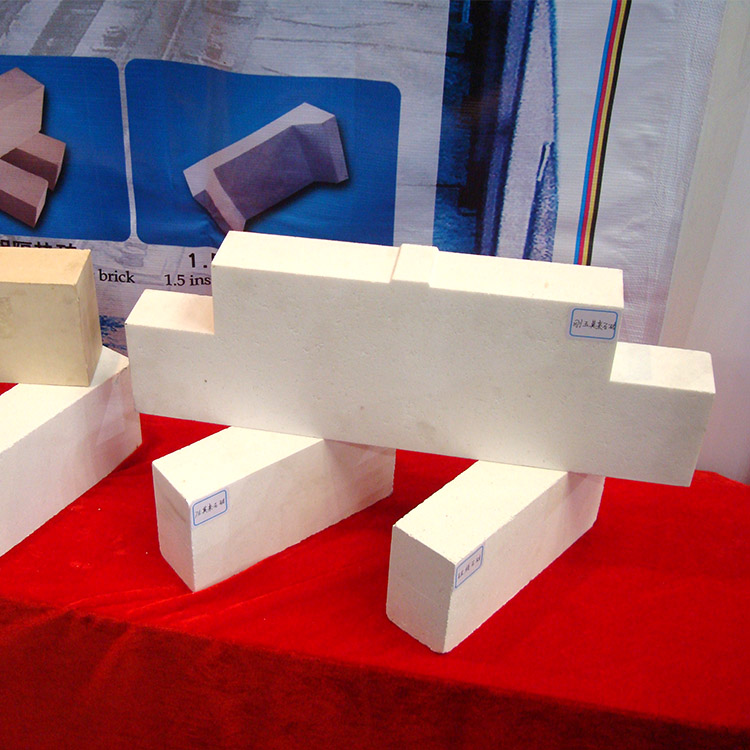

In the high - stakes world of ceramic production, the choice of kiln trays can significantly impact the efficiency, quality, and cost - effectiveness of the manufacturing process. This guide delves into the selection and life - cycle management of composite corundum mullite trays used in high - temperature firing kilns operating between 1000°C and 1400°C.

Composite corundum mullite trays offer several technical advantages, especially in terms of thermal stability, thermal shock resistance, and abrasion resistance. These properties make them a superior choice for high - temperature ceramic firing applications. For instance, compared to traditional tray materials, composite corundum mullite trays have a lower thermal expansion coefficient, which means they are less likely to deform under extreme temperature changes.

Several factors influence the performance of kiln trays. The thermal expansion coefficient, flexural strength, and abrasion resistance are key indicators. A study by a leading industry research firm shows that as the temperature rises from 1000°C to 1400°C, the thermal expansion coefficient of composite corundum mullite trays increases at a much slower rate compared to other common materials. The flexural strength also remains relatively stable, ensuring that the trays can withstand the weight of the ceramic products during firing.

| Material | Thermal Expansion Coefficient (1000 - 1400°C) | Flexural Strength (MPa) | Abrasion Resistance |

|---|---|---|---|

| Composite Corundum Mullite | 0.5 - 0.8% | 30 - 50 | High |

| Traditional Material A | 1 - 1.5% | 20 - 30 | Medium |

Different ceramic product lines, such as mosaics, sanitary ware, and roof tiles, have different temperature requirements and deformation risks. For example, mosaics usually require a firing temperature around 1000 - 1100°C. At this temperature range, composite corundum mullite trays can maintain their shape well, reducing the risk of product deformation. Sanitary ware, on the other hand, is fired at a higher temperature, around 1200 - 1300°C. The high - performance of composite corundum mullite trays ensures that they can support the heavy weight of sanitary ware products without significant deformation.

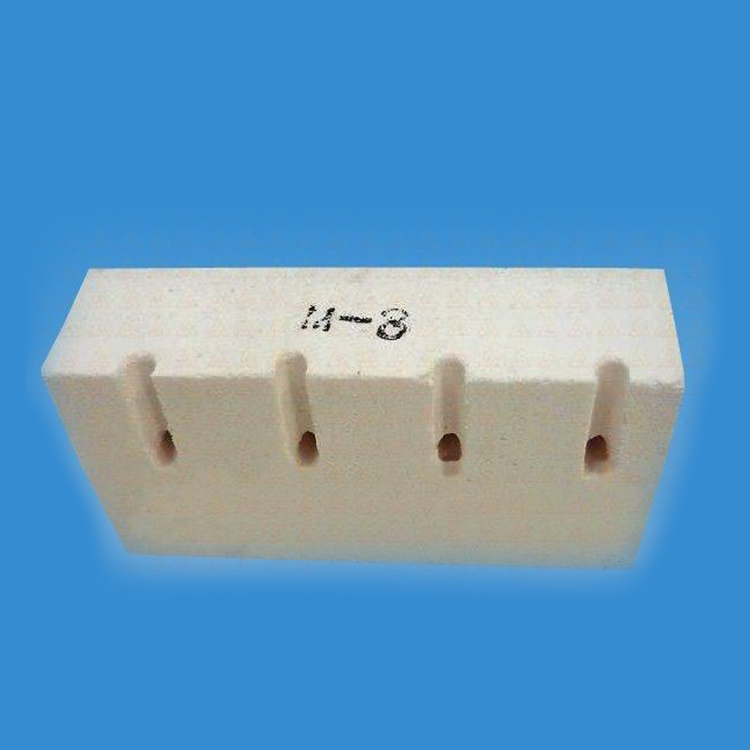

To extend the service life of kiln trays, ceramic manufacturers need to master several key strategies. First, they should be able to identify the signs of aging in trays, such as surface cracks and reduced strength. Second, choosing the right tray structure can also improve their performance. For example, some trays with a honeycomb structure have better heat distribution and mechanical properties. Finally, regular maintenance, such as cleaning and inspection, is essential to ensure the long - term performance of the trays.

A well - known ceramic production company switched from traditional trays to composite corundum mullite trays. After six months of use, they reported a 20% increase in firing yield, a 15% reduction in tray replacement frequency, and a significant decrease in product deformation rate. This case clearly demonstrates the benefits of using composite corundum mullite trays in ceramic production.

In conclusion, choosing the right kiln trays and implementing effective life - cycle management strategies can greatly enhance the efficiency and profitability of ceramic production. If you want to learn more about ceramic tray selection and optimization, click here to get the 《Ceramic Tray Selection White Paper》PDF.