In the high-temperature industrial furnace environment ranging from 1000°C to 1300°C, the stability of kiln furniture under extreme temperature differences has become a critical issue for many procurement decision-makers and technical teams. Traditional kiln furniture often fails during frequent thermal cycles, leading to increased maintenance costs and reduced production efficiency. This article combines material science with engineering practice to offer you a scientific basis for selecting kiln furniture, helping you achieve stable and efficient production.

In high-temperature industrial furnaces, traditional kiln furniture frequently encounters problems during high-frequency heating and cooling cycles. For instance, under the influence of high temperatures, traditional materials may experience significant creep, resulting in structural deformation and even cracking. According to research, traditional kiln furniture may show obvious signs of damage after about 500 thermal cycles, seriously affecting the normal operation of the furnace and reducing the production efficiency of enterprises.

Therefore, selecting kiln furniture with low creep rate and high thermal shock resistance has become an urgent need in the industry. This is where the low creep refractory materials for kiln furniture come into play, offering a long - term solution to these pain points.

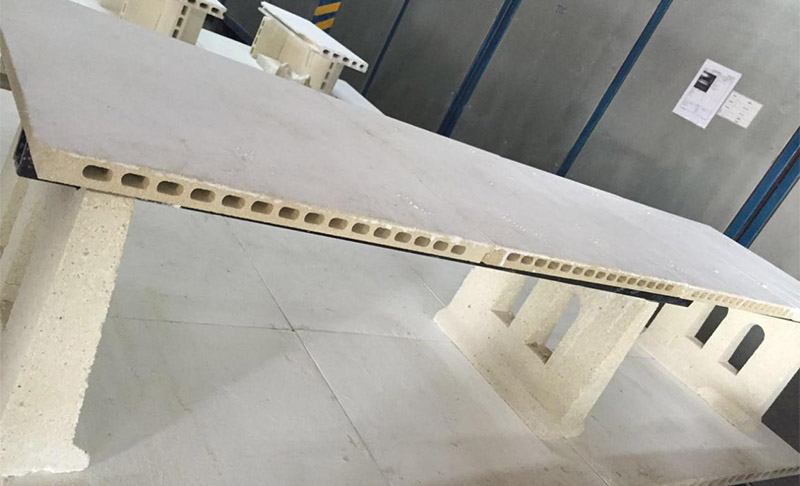

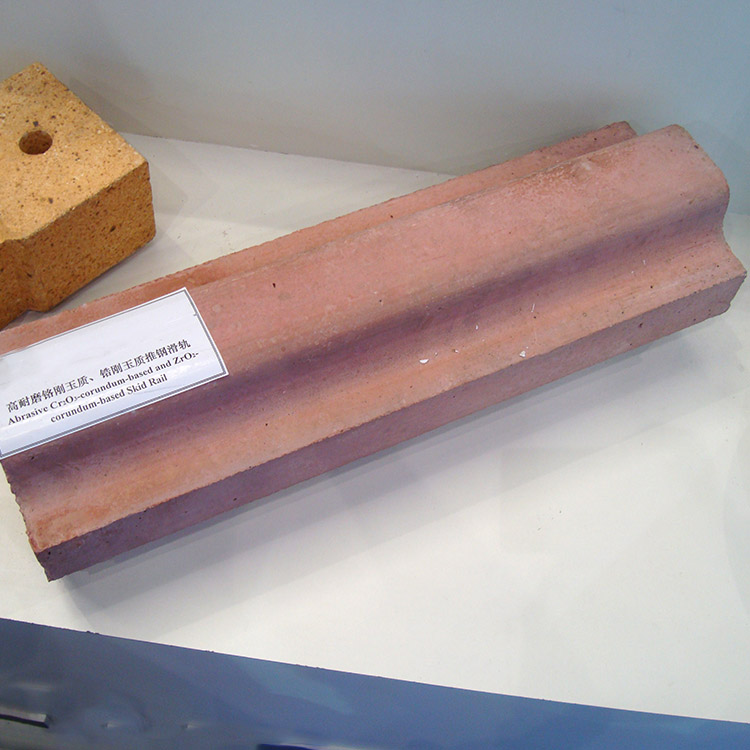

Cordierite is an ideal material for high - temperature kiln furniture. Its unique crystal structure gives it excellent performance in high - temperature environments. Cordierite has a low thermal expansion coefficient, which means it can effectively inhibit deformation during temperature changes. As shown in the comparison chart of thermal expansion coefficients below, the thermal expansion coefficient of cordierite is significantly lower than that of many traditional refractory materials.

This low thermal expansion coefficient allows cordierite to maintain its structural integrity during frequent thermal cycles, effectively preventing cracking and other damage. Additionally, cordierite has high heat resistance and chemical stability, making it suitable for various high - temperature industrial furnace environments.

Cordierite kiln furniture has shown outstanding performance in various industries such as ceramics, glass, and metallurgy. In the ceramic industry, using cordierite kiln furniture can significantly improve the product yield. For example, a ceramic enterprise reported that after replacing traditional kiln furniture with cordierite kiln furniture, the product yield increased by about 20% due to better control of product deformation during the firing process.

In the glass and metallurgy industries, cordierite kiln furniture can also effectively reduce the downtime of the furnace. Through continuous operation tests, cordierite kiln furniture can run continuously for about 800 hours without cracking, which is far superior to traditional kiln furniture. This not only improves production efficiency but also reduces maintenance costs for enterprises.

"Since using Sunrise brand cordierite kiln furniture, our furnace maintenance cost has been reduced by 30%, and the production efficiency has been significantly improved. It is truly a reliable industrial partner for us." - A ceramic enterprise procurement manager

These positive customer feedback and test data fully demonstrate the reliability and effectiveness of cordierite kiln furniture. For enterprises, choosing cordierite kiln furniture is choosing a cost - effective solution.

When selecting high - temperature kiln furniture, the following factors need to be considered:

Ensure that the selected kiln furniture can meet the temperature requirements of the furnace. Cordierite kiln furniture is suitable for the 1000°C - 1300°C temperature range, providing stable performance.

Evaluate the number of thermal shocks the furnace will experience during operation. Cordierite kiln furniture has excellent thermal shock resistance, which can meet the needs of high - frequency thermal cycles.

Ensure that the installation process of the kiln furniture is coordinated with the furnace structure to ensure its stability during operation.

Sunrise brand cordierite kiln furniture provides you with a cost - effective solution, helping you solve the stability problems of high - temperature kiln furniture. If you want to learn more about our products and get professional selection advice, click here to contact us now!