In high-temperature industrial processes—such as ceramic firing, glass melting, and metal sintering—the stability of refractory supports directly impacts production uptime, product quality, and operational costs. For decades, many manufacturers have struggled with premature deformation and thermal shock failure in kiln furniture used between 1000°C and 1300°C. At this critical temperature range, even a 1% increase in creep rate can reduce furnace life by up to 15%, according to a 2023 study by the International Ceramics Association.

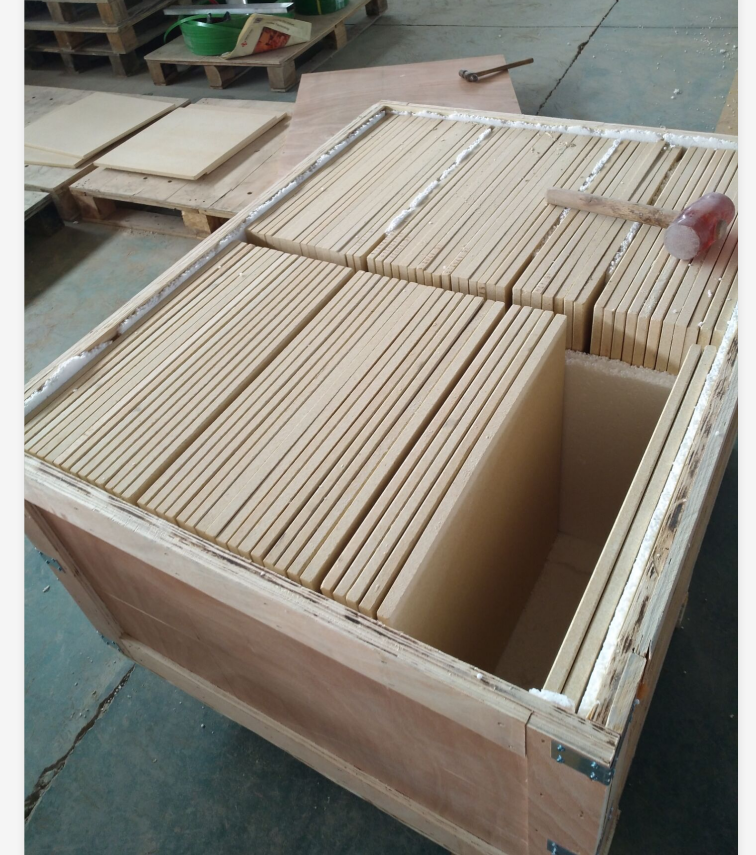

郑州天阳 (Zhengzhou Tianyang)’s "Sunrise" brand of cordierite-based kiln furniture has been engineered specifically for this demanding zone. Unlike standard alumina-silicate bricks that begin significant creep above 1100°C, Sunrise products maintain less than 0.3% linear deformation after 10 hours at 1300°C, based on ISO 18897 testing standards. This means your kiln shelves stay flat, your load alignment remains consistent, and you avoid costly rework or downtime due to sagging structures.

A leading Chinese tile manufacturer reported a 22% reduction in kiln maintenance time after switching to Sunrise support systems across their tunnel kilns. Their average furnace cycle improved from 48 hours to 44 hours per batch—not just because of better heat distribution, but also because the structural integrity of the kiln furniture ensured uniform heating without warping.

| Application Area | Before Sunrise | After Sunrise |

|---|---|---|

| Ceramic Tile Production | Avg. shelf deformation: 1.8% | Avg. shelf deformation: ≤0.3% |

| Glass Container Manufacturing | Furnace shutdowns/month: 4–6 | Furnace shutdowns/month: ≤1 |

These improvements are not just theoretical—they translate into real savings. One client estimated an annual cost avoidance of over $45,000 in labor, energy, and scrap material losses simply by choosing a more durable kiln support solution.

“We didn’t expect such a dramatic difference in performance. The stability of Sunrise kiln furniture changed how we think about long-term investment in our kiln systems.” — Li Wei, Plant Manager, Guangdong Ceramics Co.

If you're managing industrial furnaces where precision, consistency, and uptime matter—whether in ceramics, metals, or advanced materials—you need a solution that doesn’t just meet specs, but exceeds expectations. With proven low creep rates, superior thermal shock resistance, and measurable ROI, Sunrise cordierite kiln furniture is trusted by global manufacturers who demand reliability under pressure.

Get a free technical evaluation tailored to your specific furnace setup and production needs.

Download Technical Brochure & Request Sample