.jpg?x-oss-process=image/resize,h_1000,m_lfit/format,webp)

Industrial kiln furnaces operate under extreme conditions, where maintaining the refractory kiln furniture is crucial for stable and efficient production. This guide dissects the essential installation principles and daily maintenance workflow for kiln furniture, focusing on adapting to thermal expansion, managing rapid temperature variations, and implementing routine crack monitoring and repair strategies. Integrating practical insights backed by real-world industrial cases, this article equips technical and managerial professionals with actionable methods to reduce downtime and ensure product quality.

Proper installation of kiln furniture begins with acknowledging thermal expansion effects in high-temperature environments, typically ranging from 800 to 1600°C depending on the firing process. To accommodate expansion, careful layout planning with calculated spacing and flexible joints is essential. For example, allowing 2-5 mm expansion gaps between brick modules significantly reduces mechanical stress and prevents premature cracking. Employing expansion compensation materials such as high-quality ceramic blankets or fiber modules further safeguards the framework.

A recent study revealed that correctly designed installations reduce refractory failure rates by up to 40%, directly impacting maintenance cycles and costs.

Rapid heating and cooling impose significant thermal shock on kiln furniture, accelerating wear and risk of fracture. To manage this, ramp rates should be strictly controlled: gradual temperature increases of 5–15°C per minute during critical phases minimize thermal gradients. For instance, in ceramic glaze firing, a controlled soak period at peak temperature stabilizes internal stresses.

Visual inspections post heat cycles often reveal color changes or minor fissures indicating stress zones. Integrating thermocouple data analytics with manual observations helps refine temperature curve optimization for specific kiln designs.

.jpg)

Systematic daily inspections significantly improve early detection of kiln furniture deterioration. A typical checklist includes:

Consistent documentation of these findings enables trend analysis, helping predict failure points with up to 85% accuracy when supported by historical maintenance data.

Once detected, minor cracks can be effectively repaired using refractory patching mortars matched to the kiln furniture’s original composition. For example, appearances of micro-cracks in alumina brick sets are commonly repaired using high-alumina castables with heat cure procedures to restore mechanical integrity. Larger damage areas may require partial replacement with new kiln furniture components.

Preventive strategies encompass:

A ceramics manufacturer implemented a targeted kiln furniture maintenance program integrating the above techniques over 12 months. Maintenance downtime reduced by 25%, while product defects dropped 18%. Key success factors included phased thermal ramp control and deploying frequent crack monitoring schedules.

Data derived from kiln thermocouples and inspection logs enabled continuous iterative improvements in furnace operation protocols — a benchmark model for similar industrial operations.

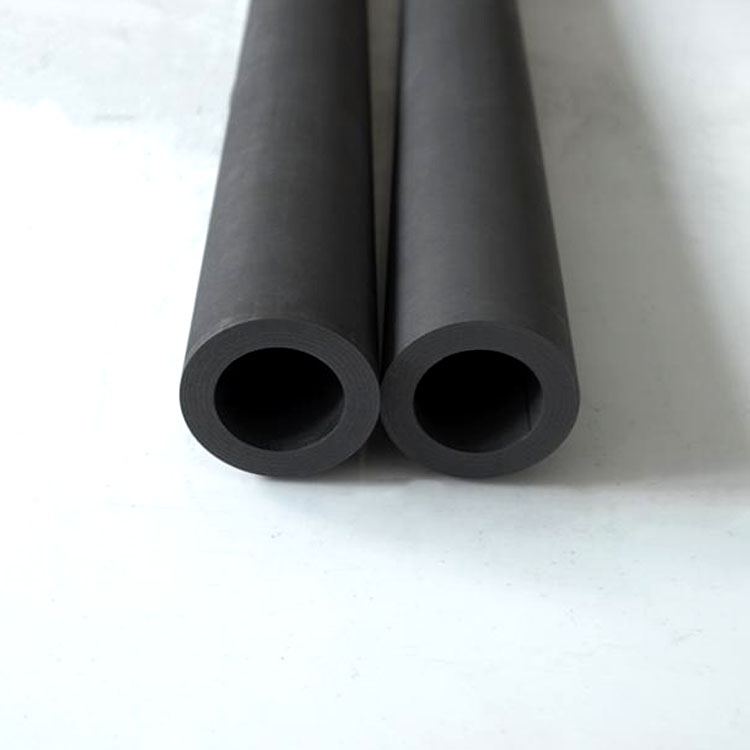

Selecting kiln furniture with superior thermal stability and low creep deformation is paramount for long-term performance. The Sunrise series by Zhengzhou Tianyang exemplifies such advanced refractory solutions. Engineered with high-purity raw materials, Sunrise kiln furniture offers excellent resistance to high temperatures (up to 1700°C) and mechanical stress, featuring:

By integrating Sunrise kiln furniture, industrial operators enhance furnace safety margins and operational longevity, ultimately driving higher production efficiency.