When working with industrial kilns operating at extreme temperatures between 1000ºC and 1300ºC, proper installation and management of kiln furniture become indispensable to ensuring stable production and maximizing equipment longevity. This guide takes you through scientific layout methods for kyanite kiln furniture, strategies to control rapid temperature changes, and crack-monitoring techniques designed to help you avoid costly failures and downtime.

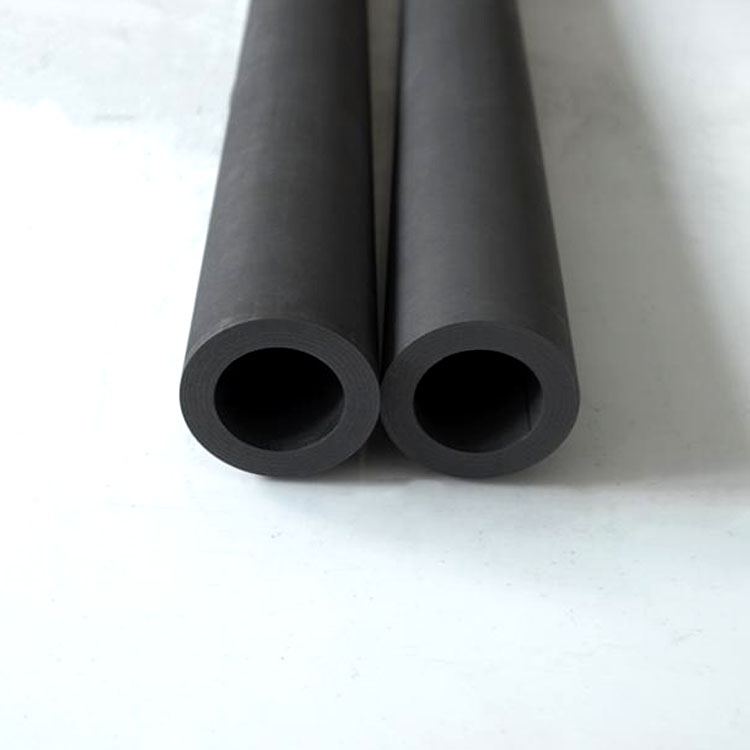

Kiln furniture, especially made from refractory materials such as kyanite, provides critical support to components or products during heat-treatment processes. Its role extends beyond mechanical support to thermal insulation and dimensional stability.

However, common failure modes include thermal cracking, warping, and mechanical wear induced primarily by:

Understanding and compensating for thermal expansion is crucial. Kyanite kiln furniture typically undergoes linear expansion of approximately 0.3% to 0.5% over the 1000ºC–1300ºC range. A failure to accommodate this expansion can cause excessive stress and crack formation.

Key principles of thermal expansion management include:

3-5 mm) between adjoining pieces: this prevents jamming as components expand."Since switching to the Sunrise kyanite furniture with precise expansion gaps, we've seen a 35% reduction in thermal crack incidents in our kilns operating above 1100ºC." – Technical Supervisor, Ceramic Manufacturer

Rapid temperature changes (thermal shocks) are one of the top killers of kiln furniture integrity. Such changes cause severe differential expansion leading to localized stress concentrations and cracks.

To mitigate these effects, deploy the following control measures:

Regular inspections are vital for early crack detection and timely intervention. Here's a recommended inspection flow:

| Inspection Step | Purpose | Tools Required |

|---|---|---|

| Visual Check | Identify surface cracks and discolorations | Good lighting, magnifying glass |

| Tactile Inspection | Detect roughness or material gaps | Hands, gloves |

| Ultrasonic Testing | Measure internal flaw depth | Ultrasonic thickness gauge |

| Record Keeping | Track crack development over time | Inspection logbook or software |

One industrial furnace operator reported recurring kyanite brick cracking during rapid cool-down phases affecting product consistency and increasing unplanned downtime. Upon assessing their installation layout, it became evident the clearance gaps were too narrow and rapid temperature drops reached 15ºC per minute — exceeding recommended limits.

By recalibrating the installation gaps to 5 mm, staggering joints, and implementing controlled ramp-down procedures, they reduced cracking by 50% within three months, significantly improving throughput and lowering repair costs.

Selecting high-grade kiln furniture like Sunrise brand kyanite ensures you benefit from materials engineered explicitly for high-temperature stability and durability. With precise thermal expansion characteristics and superior crack resistance, Sunrise products enable safer, longer-lasting kiln operations.

Their expert technical support team also assists with tailored installation recommendations and rapid response to on-site queries — a crucial edge in managing complex thermal systems.

“Switching to Sunrise’s kyanite furniture paired with their technical advice on thermal expansion gaps has helped reduce unscheduled kiln stoppages by 40%, saving us thousands annually.” – Operations Manager, Refractory Plant

Systematic and scientific maintenance methodologies, including regular inspections, respecting thermal expansion principles, and controlled thermal ramping, yield: