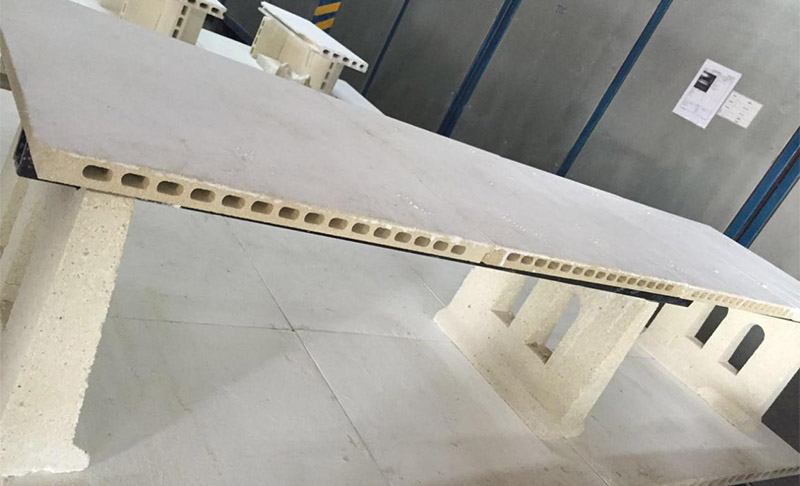

Industrial kilns operating between 1000°C and 1300°C face a persistent challenge: severe thermal shock caused by frequent heating and cooling cycles. This cyclic stress commonly leads to cracking, deformation, and eventual failure of kiln furniture — undermining production efficiency and inflating maintenance costs. Addressing this, Sunrise brand mullite kiln furniture from Zhengzhou Tianyang Refractory Materials Co., Ltd. leverages advanced low-creep materials technology and innovative structural design to deliver unparalleled thermal shock resistance, significantly extending service lifespan in demanding environments.

The superior performance of Sunrise mullite kiln furniture stems from two key material characteristics: low creep rate and exceptional thermal shock tolerance. Mullite's intrinsic crystal structure—a stable orthorhombic lattice with strong directional bonding—ensures minimal atomic diffusion at elevated temperatures, effectively reducing plastic deformation or “creep.” Customized material formulations enriched with controlled alumina content and optimized grain size distribution further fortify the mechanical matrix against high-temperature stress.

This low creep behavior allows kiln supports to maintain dimensional integrity under sustained high-temperature loads, lowering risks of warping or sagging during prolonged operation. Complementing this, Sunrise’s innovative manufacturing processes enhance microstructural uniformity, which translates into superior resistance against rapid temperature fluctuations, a critical factor in thermal shock durability.

“Since integrating Sunrise mullite kiln furniture into our glass manufacturing line, downtime due to kiln furniture failure has dropped by over 40%. The enhanced thermal stability directly improved our throughput and cut maintenance costs.” — Technical Manager, European Glassworks Ltd.

Sunrise mullite kiln furniture has demonstrated remarkable performance across several sectors where kiln reliability is paramount:

Extensive field data confirm Sunrise’s ability to outperform standard alumina-silicate kiln furniture by increasing service life by 30%-50%, depending on operating conditions.

Comparative tests conducted under simulated industrial conditions reveal striking differences in deformation rates between traditional kiln furniture and Sunrise mullite units:

| Material | Average Creep Rate (% strain per 100hr at 1200°C) | Thermal Shock Cycles to Failure |

|---|---|---|

| Traditional Alumina-Silicate | 0.05% | Around 40 cycles |

| Sunrise Mullite Kiln Furniture | 0.012% | 70+ cycles |

This data reflects a more than 75% reduction in creep rate and nearly doubling of thermal shock endurance under consistent test parameters, highlighting Sunrise mullite’s optimized resistance to failure modes common in high-frequency kiln cycling.

Choosing kiln furniture demands a nuanced assessment of operational parameters including:

Consulting with Zhengzhou Tianyang’s technical team enables precise matching of Sunrise kiln furniture products to specific operational demands, maximizing both lifespan and kiln uptime.