In the high - temperature sintering processes of industrial kilns, traditional kiln furniture has long been plagued by issues. Creep and thermal shock failures are the main culprits, leading to frequent kiln shutdowns. On average, traditional kilns may experience shutdowns 3 - 5 times more frequently than those using advanced kiln furniture. These shutdowns not only disrupt production schedules but also significantly increase costs. Maintenance and replacement expenses can account for up to 20% of the total production cost in some cases.

Zhengzhou Tianyang Refractory Materials' Sunrise brand cordierite kiln furniture uses an advanced material formula. The specific combination of raw materials, such as high - purity alumina and silica, precisely controls the creep behavior. The unique chemical composition restricts the movement of atoms at high temperatures, reducing the tendency of the material to deform under load. In the temperature range of 1000°C–1300°C, the creep rate of Sunrise kiln furniture is as low as 0.1% - 0.3%, compared to 1% - 3% of traditional kiln furniture.

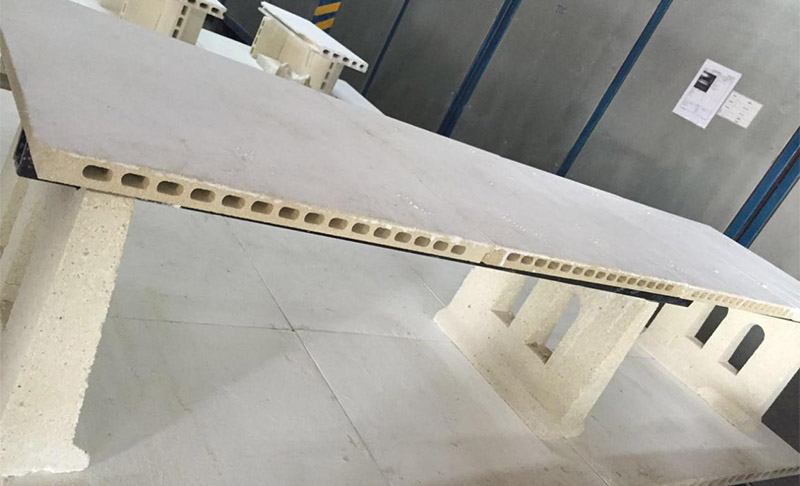

The microstructure of Sunrise kiln furniture plays a crucial role in enhancing thermal shock resistance. Its fine - grained and porous structure allows it to absorb and dissipate thermal stress effectively. When exposed to rapid temperature changes, the material can withstand the strain without cracking. The coefficient of thermal expansion is carefully adjusted to match the working conditions, which further improves its ability to resist thermal shock.

In ceramic firing processes, Sunrise kiln furniture provides stable support. It can withstand the repeated heating and cooling cycles without significant deformation, ensuring the quality of ceramic products. The reduced cracking rate of ceramic products during firing can be up to 80% compared to using traditional kiln furniture.

For metal heat treatment, the high - temperature stability of Sunrise kiln furniture is highly beneficial. It can maintain its shape and strength during the heating and quenching processes, improving the precision of metal parts. The service life of the kiln furniture in metal heat treatment applications can be extended by 2 - 3 times compared to traditional options.

In the preparation of new energy materials, such as lithium - ion battery cathodes, the strict temperature and environmental requirements demand high - performance kiln furniture. Sunrise kiln furniture's low creep and high thermal shock resistance ensure the consistency and quality of new energy materials, reducing production waste by up to 50%.

Real - world data shows the superiority of Sunrise kiln furniture. In a ceramic factory, after switching to Sunrise kiln furniture, the use cycle was extended by 150%. Maintenance costs decreased by 30%. In a metal heat treatment plant, the production efficiency increased by 25% due to fewer kiln shutdowns. These data clearly demonstrate the economic benefits of using Sunrise kiln furniture.

"Since we started using Sunrise cordierite kiln furniture, our production has become much more stable. The reduction in maintenance and replacement costs has directly improved our bottom line." - A customer from a ceramic manufacturing company

From a user's perspective, the investment in Sunrise kiln furniture is a wise decision. The long - term economic benefits outweigh the initial cost. By reducing production disruptions and maintenance expenses, the kiln furniture helps companies achieve cost - effective production. It provides a reliable solution for procurement decision - makers and technical teams to optimize their kiln operations.

In the context of green manufacturing, there is a growing demand for high - stability refractory materials. Sunrise kiln furniture meets these requirements by reducing energy consumption and waste generation. Its long service life and high efficiency contribute to a more sustainable production process.

Choose Sunrise, and you're not just buying a product; you're securing long - term stable profits. Discover the efficiency and value of Sunrise kiln furniture for your business by clicking here.