In high-frequency heating industrial environments, kiln components often face accelerated wear due to thermal shocks and creep deformation, significantly reducing their operational lifetime. This enduring challenge costs industries in downtime and maintenance overhead. Zhengzhou Tianyang Refractory Materials Co., Ltd., under its reputable "Sunrise" brand, pioneers advanced sillimanite kiln furniture specifically engineered for superior low creep rates and thermal shock resistance. Designed to perform reliably at temperatures ranging between 1000°C and 1300°C, these kiln supports optimize productivity while minimizing service interruptions.

Suffering from abrupt temperature fluctuations, industrial kiln furniture undergoes significant thermal stress, often leading to crack initiation and propagation. Simultaneously, at elevated temperatures, creep — a time-dependent plastic deformation under sustained load — progressively alters the ceramic microstructure. Typical refractory materials experience creep deformation rates of 5×10-5 to 1×10-4 %/h at 1200°C, accelerating mechanical failure and forcing premature replacement cycles.

Conventional kiln supports lack tailored formulations and structural innovations needed to endure such stresses during rapid heating and cooling cycles prevalent in textile, ceramics, and chemical production lines.

"Sunrise" sillimanite kiln furniture integrates a proprietary refined chemical composition emphasizing high-purity aluminosilicate phases. The material exhibits a remarkable low creep rate of approximately 1×10-6 %/h at 1200°C, outperforming industry averages by up to 20 times. This is attributed to optimized grain boundary characteristics and controlled porosity levels around 12–15%, balancing strength and thermal insulation.

Structurally, the kiln furniture incorporates graded microstructures to dissipate thermal stress effectively. The outer layers possess enhanced toughness to resist crack initiation, while the core maintains rigidity to support mechanical loads. This architecture mitigates thermal shock, achieving at least 80 cycles of abrupt temperature change at 1100°C without significant degradation.

Deployed across multiple industrial kiln installations, "Sunrise" sillimanite supports have demonstrated a 25% extension in average service life versus traditional mullite or alumina-based alternatives under 1000°C–1300°C operational ranges. Key performance indicators include:

These verifiable gains translate into minimized downtime and improved throughput, particularly for textile ceramic firing and rapid batch chemical processes demanding swift temperature ramp-up and cooldown.

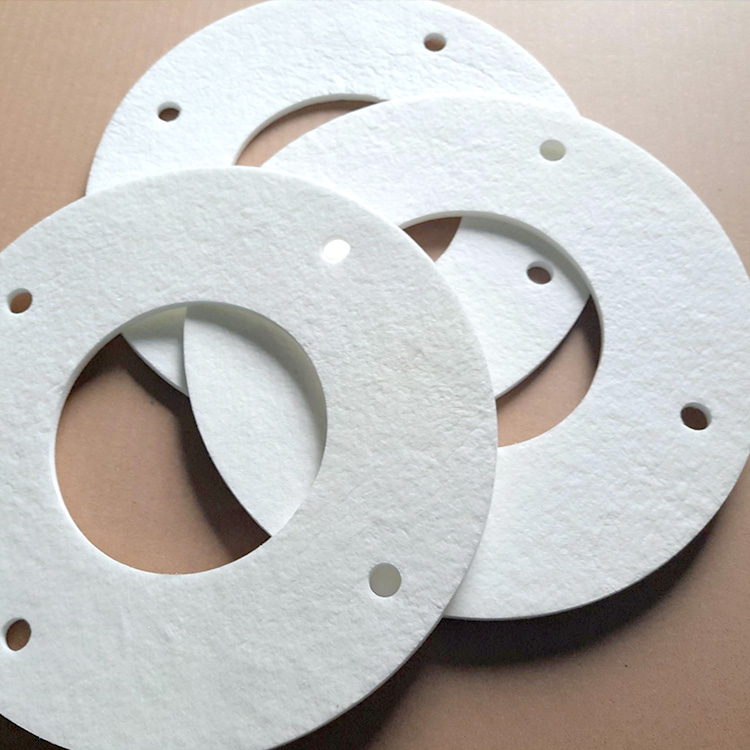

The "Sunrise" sillimanite kiln furniture is engineered to seamlessly integrate within various kiln support systems, including ring supports, post supports, and base plates. Their compatibility with differing kiln designs offers procurement teams flexibility while ensuring consistent performance metrics.

While upfront investment may marginally exceed standard refractories, lifecycle cost analyses reveal total cost savings upward of 18% when factoring in extended service intervals, lower replacement frequency, and reduced energy consumption due to improved thermal efficiency.