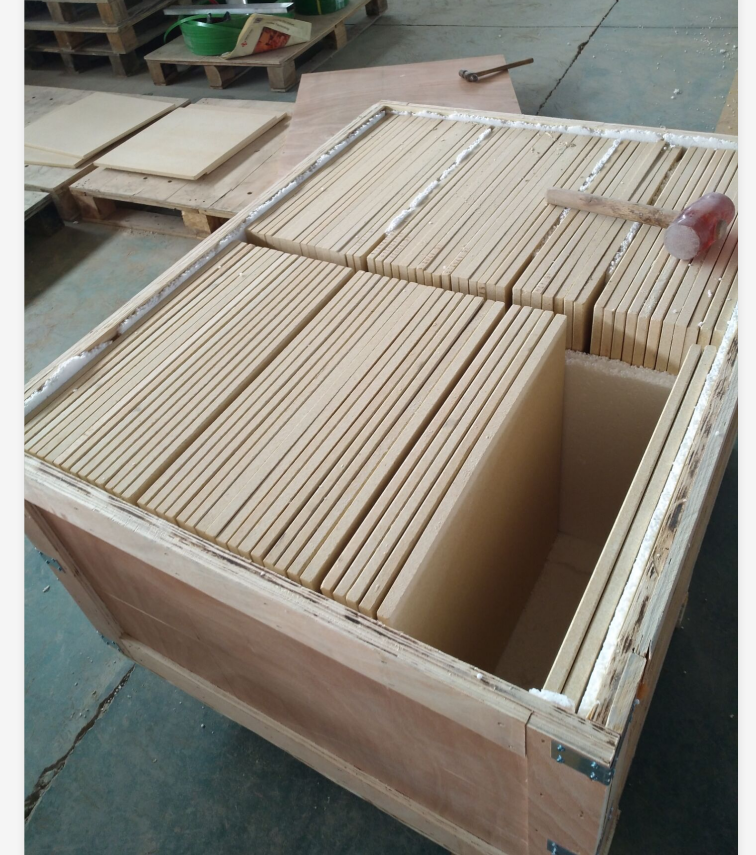

Industrial kilns operating at extreme temperatures between 1000ºC and 1300ºC require components that can withstand prolonged thermal stress without compromising structural integrity. Among these components, kiln furniture plays a critical role in supporting loads while resisting deformation and thermal shocks. This article delves into the low creep rate characteristic of cordierite-based kiln furniture, exploring its underlying material science and how it translates to exceptional durability and efficiency in demanding export markets.

Creep refers to the slow, permanent deformation of materials under mechanical stress at high temperatures. For kiln furniture, a low creep rate means minimal shape change over long-term exposure to high heat and load, which directly correlates to longer operational life and fewer interventions for replacement.

Cordierite, a magnesium iron aluminum cyclosilicate ceramic, exhibits an optimal balance of thermal stability and mechanical strength. Its unique crystalline structure, coupled with low thermal expansion coefficients (typically around 2–3 × 10−6/K), reduces internal stresses during heating and cooling cycles, enhancing its thermal shock resistance.

Various industries face unique kiln operation challenges. Ceramic manufacturers regularly perform multiple heating and cooling cycles daily, posing high risks for thermal shock-induced cracking. Meanwhile, metallurgy sectors demand robust kiln furniture that can maintain support under heavy loads and fluctuating thermal conditions.

Sunrise's cordierite kiln furniture has proven its effectiveness in these scenarios by substantially mitigating mechanical creep and resistive against cracking due to rapid temperature changes. This translates into fewer replacements, reduced maintenance expenditures, and enhanced production continuity.

| Region | Customer Feedback | Observed Creep Rate Reduction | Maintenance Cost Reduction |

|---|---|---|---|

| Southern Europe | High kiln uptime; decreased crack rate | ~35% | ~30% |

| Southeast Asia | Repeat customer due to product reliability | ~40% | ~25% |

| East Asia | Improved kiln cycle flexibility | ~38% | ~28% |

To maximize performance, key parameters should guide kiln furniture selection:

Following these guidelines extends service life and fosters cost-effective kiln operation.

As a globally recognized manufacturer, Sunrise brings decades of R&D experience and stringent quality control to the industrial kiln sector. Clients benefit not only from superior material performance but also from professional pre-sales consultancy, customized technical support, and robust after-sales service worldwide.

This level of commitment translates to assured reliability and peace of mind for procurement managers and engineering teams navigating increasingly competitive markets.

Are you struggling with frequent kiln furniture replacements due to thermal damage? Explore how low creep rate solutions can bring long-term savings.