In the high - temperature firing process of ceramic products, the uneven heating of trays often leads to common defects such as warping and cracking. These issues not only affect the appearance of the products but also significantly reduce the yield rate. For instance, in some traditional ceramic factories, the deformation rate of products during firing could reach up to 30%, which is a huge loss for the enterprises.

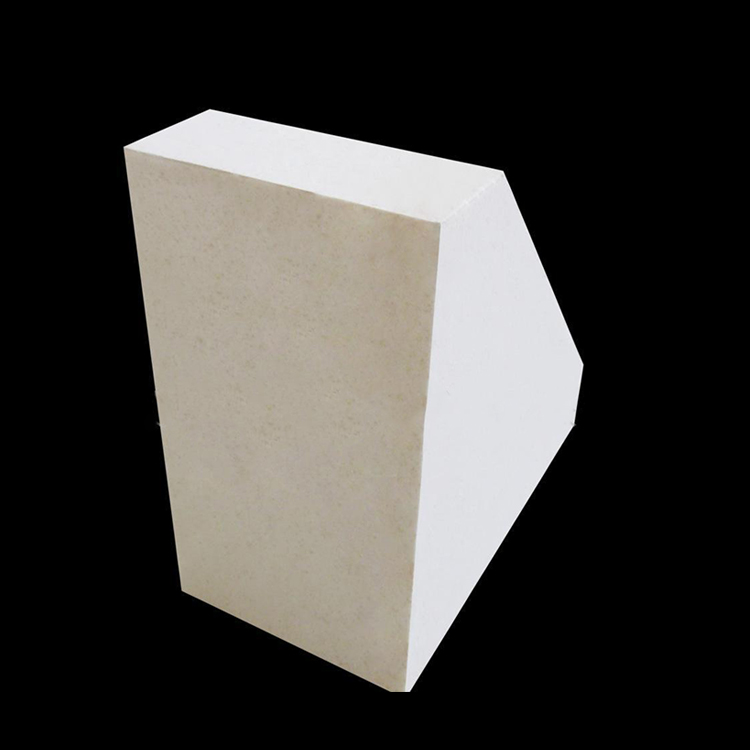

When it comes to the tray materials, composite corundum - mullite trays stand out. A technical expert once said, 'Composite corundum - mullite has excellent thermal stability and high thermal conductivity, which are crucial for the uniform heating of ceramic products during firing.' This material can better withstand the high - temperature environment in the kiln and transfer heat more efficiently, reducing the temperature difference between different parts of the ceramic products and thus minimizing the occurrence of defects.

The structural design of trays plays a vital role in improving the heat transfer uniformity. The distribution of grooves on the tray surface can effectively change the flow path of heat, making the heat transfer more evenly. For example, by optimizing the groove distribution, the heat transfer efficiency can be increased by about 20%. The thickness gradient of the tray also affects the heat transfer. A well - designed thickness gradient can ensure that different parts of the ceramic product receive appropriate heat, further reducing the temperature difference.

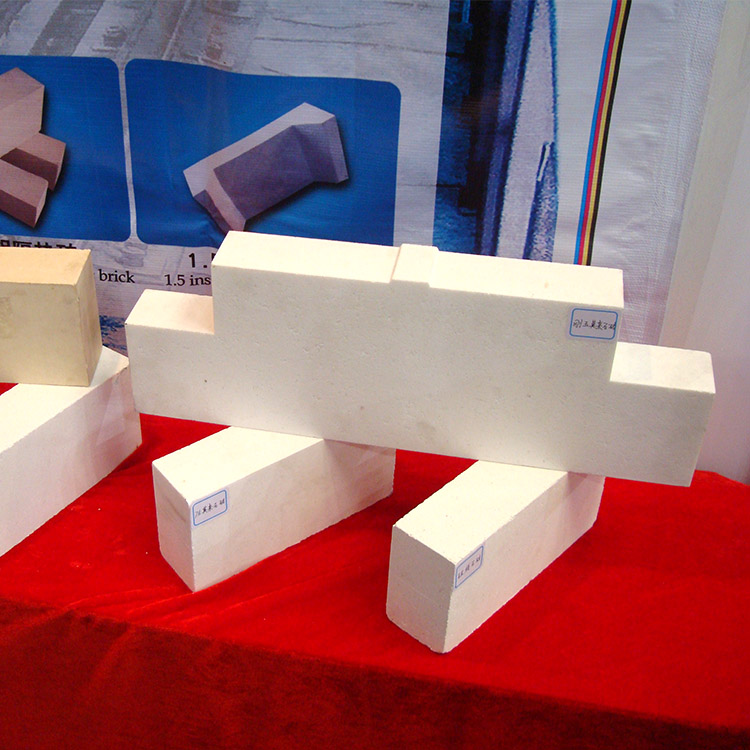

The installation method of trays is another critical factor. The setting principle of stacking spacing is based on ensuring uniform heat flow between trays. If the stacking spacing is too small, the heat cannot be transferred smoothly, resulting in local overheating; if it is too large, it will waste space in the kiln. Through practical experience, we have found that an appropriate stacking spacing can reduce the deformation rate by about 15%. The layout of positioning holes also affects the positioning accuracy of trays. Precise positioning can ensure that each ceramic product is in the correct position during firing, which is beneficial to the uniform heating of products.

Let's take a look at a real - world application case. A ceramic factory used to have a product deformation rate of 25% before using our optimized trays. After adopting our composite corundum - mullite trays with optimized structure and installation methods, the deformation rate dropped to 10%, and the yield rate increased from 75% to 90%. The following table shows the comparison:

| Before Improvement | After Improvement |

|---|---|

| Deformation Rate: 25% | Deformation Rate: 10% |

| Yield Rate: 75% | Yield Rate: 90% |

To ensure the best firing effect, on - site detection and adjustment are necessary. We usually use infrared thermometers to measure the temperature of different parts of the trays and ceramic products, visually observe the appearance of products during firing, and conduct test firings to verify the firing effect. Based on these detection results, we can quickly adjust the stacking spacing, positioning of trays, etc. For example, if the infrared thermometer shows that the temperature of a certain area is too high, we can increase the stacking spacing in that area.

The compatibility between trays and kiln cars is also very important. A well - matched tray - kiln car system can ensure the consistency of the overall thermal field in the kiln. If the trays do not match the kiln cars, it may lead to uneven heat distribution, which will affect the firing quality of ceramic products.

We have provided customized tray solutions for many ceramic factories. Our products have been widely used in industrial scenarios, and we offer professional technical support. If you are also troubled by the high deformation rate of ceramic products during firing, click here to learn more about our products and solutions.