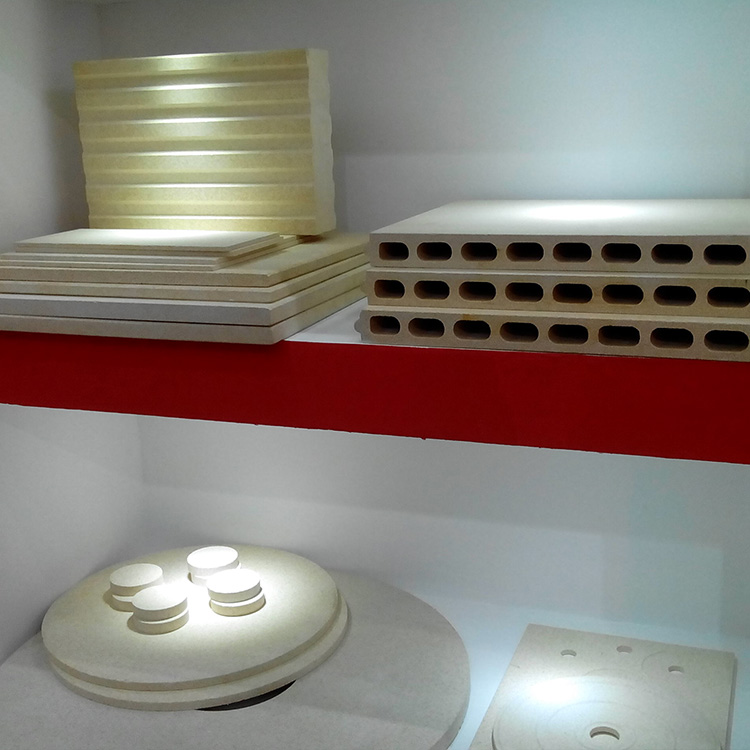

In the field of magnetic material sintering, the choice of trays plays a crucial role in ensuring product quality and production efficiency. Composite corundum mullite trays have emerged as a popular option due to their unique material properties. This article delves into the application of these trays in magnetic material sintering, aiming to provide practical solutions to common problems and enhance users' understanding of the sintering process.

Composite corundum mullite trays are made of a special combination of corundum and mullite, which endows them with high refractoriness, good thermal shock resistance, and low thermal conductivity. These properties are particularly important in the sintering process of magnetic materials such as permanent ferrite and NdFeB. For example, the high refractoriness allows the trays to withstand high temperatures during sintering, while the good thermal shock resistance prevents them from cracking due to rapid temperature changes. According to industry data, compared with traditional trays, composite corundum mullite trays can reduce energy consumption by about 15% during the sintering process.

Micro - cracks in trays can lead to serious magnetic material inclusion defects. The generation of micro - cracks is mainly due to thermal stress, chemical reactions, and mechanical damage. When micro - cracks occur, impurities in the tray can enter the magnetic material during the sintering process, resulting in inclusion defects. A typical case study shows that in a certain magnetic material production plant, about 10% of the products had inclusion defects due to tray micro - cracks. By analyzing the microstructure of the defective products, it was found that the impurities from the trays were the main cause.

.jpg)

In a high - temperature reducing atmosphere, the stability of composite corundum mullite trays is crucial to prevent metal pollution. Research shows that under a reducing atmosphere at 1200°C, the trays may react with some metal elements, resulting in metal pollution of the magnetic materials. To prevent this, special coating technologies and atmosphere control methods can be adopted. For example, applying a protective coating on the surface of the tray can reduce the contact between the tray and the metal elements, thereby reducing the risk of metal pollution. According to experimental data, the use of a protective coating can reduce metal pollution by about 80%.

Thermal stress cracking, surface oxidation, and residual adhesion are common problems in the use of trays. Thermal stress cracking is mainly caused by uneven temperature distribution during the heating and cooling process. Surface oxidation occurs when the tray is exposed to an oxidizing atmosphere at high temperatures, which can reduce the performance of the tray. Residual adhesion is caused by the adhesion of magnetic materials to the tray surface during sintering. To solve these problems, adjusting the heating and cooling rates, controlling the atmosphere, and using special cleaning agents are effective methods. For example, by reducing the heating rate from 10°C/min to 5°C/min, the occurrence of thermal stress cracking can be significantly reduced.

Optimizing the sintering process parameters is essential to improve the quality of magnetic materials. The heating rate, holding time, and atmosphere composition are all important factors. For example, a proper heating rate can ensure uniform temperature distribution in the magnetic material and the tray, reducing the occurrence of defects. Industry standards recommend a heating rate of 3 - 5°C/min for most magnetic material sintering processes. In addition, matching the atmosphere composition with the material properties can also improve the sintering quality. For example, in the sintering of NdFeB, a reducing atmosphere with a certain hydrogen content can prevent oxidation and improve the magnetic performance of the product.

In conclusion, composite corundum mullite trays have great potential in magnetic material sintering. By understanding their material properties, preventing micro - cracks, ensuring stability in high - temperature reducing atmospheres, and optimizing the sintering process, the quality and production efficiency of magnetic materials can be significantly improved. If you want to learn more about customized technical support and solutions for magnetic material sintering trays, please click here.