In the high - temperature chemical industry, the performance requirements for refractory materials in reactors are extremely strict. Zhengzhou Tianyang Refractory Materials Co., Ltd. has introduced common magnesium chromium bricks, which are a reliable choice for high - temperature chemical scenarios.

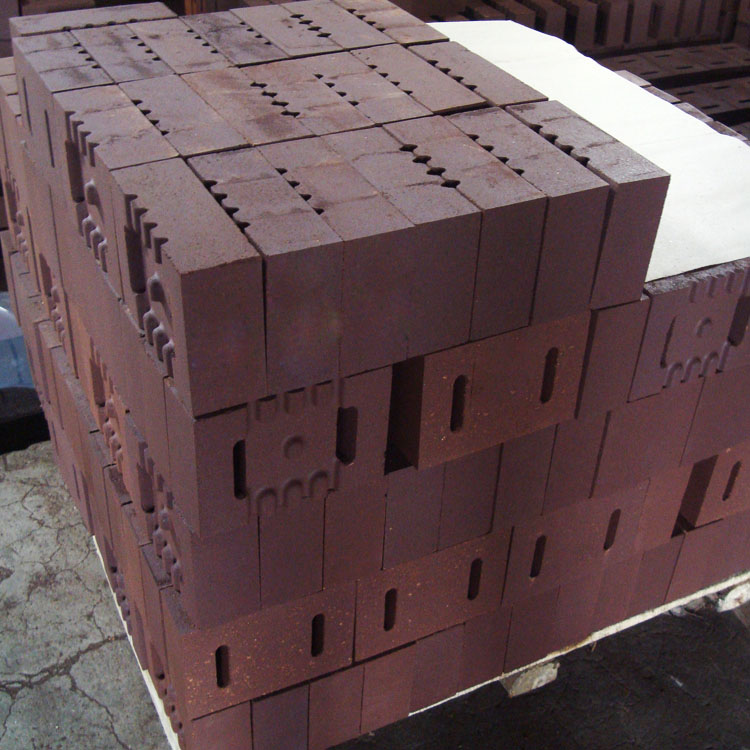

These common magnesium chromium bricks are made of sintered magnesia and refractory - grade chrome ore through a silicate bonding process. The carefully selected raw materials play a crucial role in determining the final performance of the bricks. Sintered magnesia provides high - temperature strength, while refractory - grade chrome ore enhances corrosion resistance. With a specific raw material ratio of 70% sintered magnesia and 30% refractory - grade chrome ore, and a unique silicate bonding method, the bricks achieve excellent overall performance.

A performance comparison chart between common magnesium chromium bricks and traditional magnesium bricks shows significant differences. In terms of thermal shock performance, traditional magnesium bricks may crack after 10 - 15 thermal cycles, while common magnesium chromium bricks can withstand more than 30 thermal cycles without obvious damage. In terms of anti - erosion ability, in a corrosive environment with a high - temperature chemical medium of 1500°C, the weight loss rate of traditional magnesium bricks is about 15% after 100 hours, while that of common magnesium chromium bricks is less than 5%.

"The common magnesium chromium bricks provided by Zhengzhou Tianyang have greatly improved the service life of our reactors. We used to replace the lining bricks every six months, but now it can be extended to one and a half years." - A chemical plant in South Europe

In South Europe, these bricks have been used in many chemical plants. In a large - scale chemical project in Italy, the use of common magnesium chromium bricks has increased the operating efficiency of the reactor by 20% and extended the maintenance cycle from 8 months to 18 months. In Southeast Asia, in a chemical plant in Indonesia, the application of these bricks has reduced the production cost by 15% due to less frequent replacement of refractory materials. In the Middle East, in a petrochemical project in Saudi Arabia, the common magnesium chromium bricks have withstood the harsh high - temperature and high - pressure environment, ensuring the long - term stable operation of the equipment.

Zhengzhou Tianyang has established a stable supply chain system. With an annual production capacity of more than 50,000 tons of common magnesium chromium bricks, it can ensure timely delivery to customers around the world. In addition, the company provides a comprehensive after - sales service system, including on - site installation guidance, regular equipment inspection, and rapid response to customer problems. This supply chain and after - sales service guarantee system forms a positive closed - loop between product value and customer satisfaction.

Are you facing similar challenges in high - temperature chemical scenarios? Do you want to improve the efficiency and lifespan of your equipment? If so, Zhengzhou Tianyang's common magnesium chromium bricks, which have been verified in multiple international projects for their stability, can be your ideal solution. Click here to learn more about high - temperature chemical refractory materials