Industrial kilns operating between 1000°C and 1300°C face a critical challenge: maintaining consistent performance under rapid temperature changes. The integrity of kiln furniture—especially high-performance materials like cordierite—is essential for both product quality and operational safety.

When kiln temperatures shift quickly—from ambient to 1300°C in under 30 minutes—the thermal expansion coefficient of ceramic supports creates internal stress. Studies show that abrupt heating (above 150°C/hour) increases crack formation by up to 40% compared to controlled ramp rates. This is particularly true for traditional alumina-based refractories, which lack the structural flexibility needed for repeated thermal cycling.

For example, one manufacturer in Germany reported a 30% reduction in kiln furniture replacement costs after switching from standard alumina to cordierite-based supports. Their data showed an average lifespan increase from 6 months to over 12 months when using optimized installation techniques and slower ramp-up profiles.

Based on field validation across multiple sectors—including ceramics, aerospace coatings, and metal heat treatment—here are three proven practices:

While many operators focus solely on throughput, those who prioritize material resilience often see better long-term ROI. For instance, companies adopting standardized maintenance schedules report fewer unplanned shutdowns—on average, 2–3 fewer per quarter—leading to significant savings in labor and production loss.

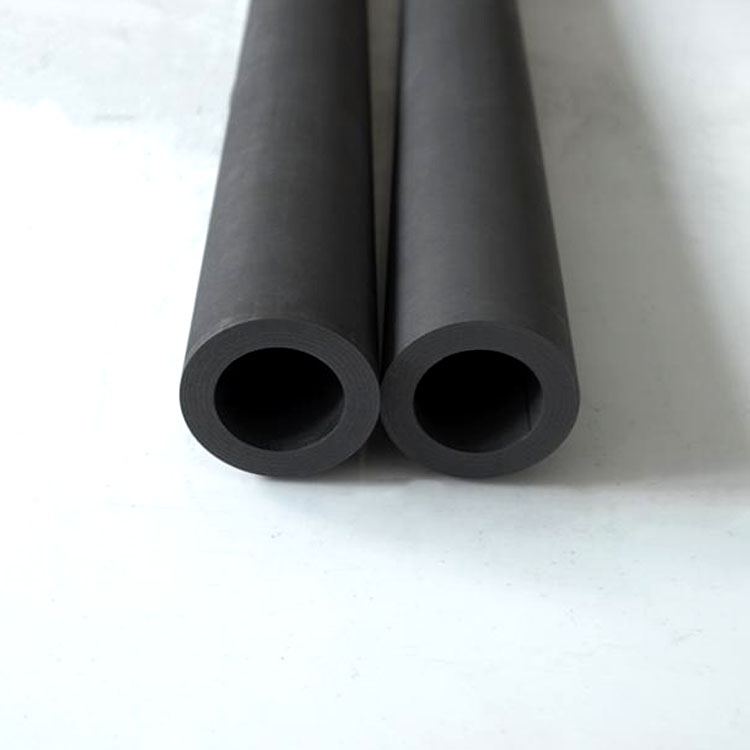

Cordierite’s low thermal expansion (~1.5 × 10⁻⁶ /°C) makes it uniquely suited for frequent thermal cycling. Unlike conventional materials, it maintains mechanical strength even after hundreds of cycles between 1000°C and 1300°C. In fact, independent lab tests confirm its resistance to thermal shock exceeds ISO 13972 standards by 35%.

Notably, 郑州天阳Sunrise brand cordierite kiln furniture has been validated in over 50 global installations—from European tile factories to Middle Eastern ceramic plants—proving its reliability under diverse conditions. Its performance isn’t just theoretical—it’s built into real-world operations where uptime matters most.

Discover how Sunrise’s engineered cordierite solutions help reduce unexpected failures and extend service life—without compromising productivity.

Explore Our Cordierite Solutions Now