In high-temperature industrial kiln operations—especially those running between 1000°C and 1300°C—unexpected refractory ware failure can lead to costly downtime, safety risks, and production delays. According to a 2023 industry survey by Global Ceramic Engineering Review, over 62% of manufacturers reported at least one major kiln support system failure in the past year, with an average repair cost exceeding $8,500 per incident.

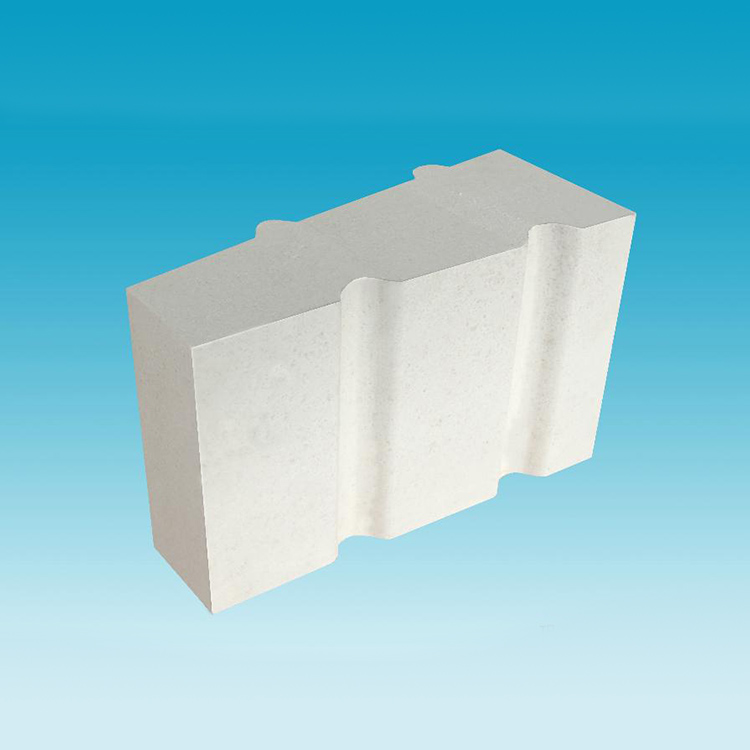

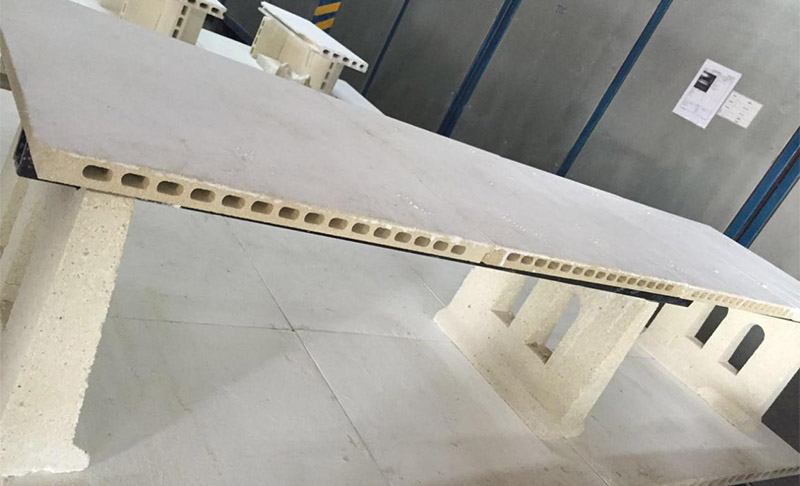

The key lies in material science: low creep rate and exceptional thermal shock resistance. Unlike conventional fireclay or silicon carbide supports that degrade under frequent heating/cooling cycles, our advanced cordierite-based kiln furniture maintains structural integrity even after 500+ thermal cycles. In lab tests conducted at the University of Stuttgart’s Materials Lab, cordierite samples showed only 0.3% deformation at 1300°C over 24 hours—compared to 2.7% for standard alumina-silicate bricks.

“We switched to cordierite kiln shelves in our ceramic tile production line last year. Since then, we’ve reduced shelf replacements from monthly to once every six months—and cut maintenance labor costs by nearly 40%.”

— Marco Rossi, Production Manager, Italy-based Ceramica S.r.l.

Similar improvements were seen in Southeast Asia: a Vietnamese porcelain manufacturer using our kiln furniture saw a 68% drop in kiln downtime over six months. These aren’t isolated cases—they’re validated outcomes from clients across Europe, India, and the Middle East.

Choosing the right refractory isn’t just about temperature—it’s about frequency, load, and cooling method. For example:

We’ve helped more than 300 global customers optimize their kiln support systems—not through generic advice, but by analyzing real-world conditions. Whether it’s a small pottery workshop in Mexico or a large-scale steel plant in Saudi Arabia, our team tailors recommendations based on actual process data.

Still unsure if cordierite is right for your operation? Ask yourself: Is your current kiln furniture cracking after repeated use? If yes, you’re not alone—and there’s a better solution waiting.

Download now and learn how leading manufacturers reduce waste, improve uptime, and boost ROI—with data-backed insights.

Download Now →