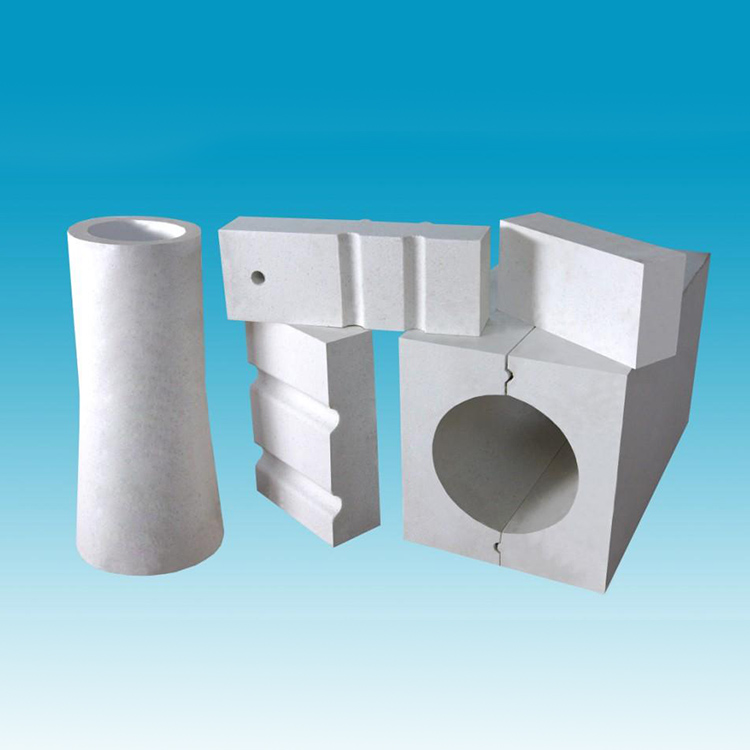

For ceramic manufacturing enterprises, choosing the right kiln tray material is pivotal to product quality, operational efficiency, and cost management. This article delves into a comparative analysis between modern composite corundum-mullite trays and traditional refractory bricks, focusing on crucial parameters such as thermal stability, thermal shock resistance, wear resistance, and chemical inertness. Tailored application insights for ceramic mosaics, sanitary ware, and roof tiles provide actionable guidance for technical managers and procurement decision-makers.

Understanding the technical requirements behind kiln tray materials helps align material properties with specific ceramic firing processes. The following four indicators are fundamental in evaluating tray suitability:

| Performance Indicator | Composite Corundum-Mullite | Traditional Refractory Brick |

|---|---|---|

| Thermal Stability (Deformation at 1400°C) | Low deformation < 0.2% | Higher deformation ~0.8% - 1.0% |

| Thermal Shock Resistance (Cycles to failure) | Up to 50 rapid heat/cool cycles | Around 20 cycles |

| Wear Resistance (Abrasion loss rate) | Abrasion loss ≤ 3% per 100 cycles | Abrasion loss ~7% per 100 cycles |

| Chemical Inertness (Resistance to glaze penetration) | Excellent, minimal reaction | Moderate, prone to minor infiltration |

The superior thermal shock resistance of composite corundum-mullite significantly reduces kiln downtime caused by tray cracking. Additionally, lower deformation rates ensure consistent product flatness, improving the fired ceramic quality.

Ceramic trays' functional demands shift with the type of product being fired:

Choosing the right tray type based on product and kiln firing parameters directly impacts yield rates and maintenance cycles.

Kilns operating between 1000°C to 1400°C impose varying stresses on trays, necessitating tailored monitoring and maintenance regimes:

Implementing regular non-destructive testing (visual inspections, ultrasonic scanning) every 100 firing cycles can pre-empt tray failure. Data-driven lifespan management extends tray usability while optimizing kiln uptime.

• For production lines firing high-value sanitary ware and tiles with strict dimensional tolerances, prioritize composite corundum-mullite trays despite higher upfront cost. Enhanced durability and stability justify ROI within 6-12 months.

• For less demanding products or pilot production, traditional refractory bricks remain economically viable, provided rigorous inspection schedules and lifespan tracking are enforced.

• Integrate kiln tray performance data into quality management systems for actionable insight and predictive maintenance.

Empower your kiln operations by accessing our comprehensive Ceramic Tray Selection Whitepaper – Unlock Precision & Longevity now.

Join the Ceramic Kiln Technology Expert Community to engage with industry leaders and stay ahead in thermal materials innovation.