Selection Guide for High-Temperature Kiln Furniture Materials: Optimizing Performance in 1000-1300ºC Processes

09 07,2025

Technical knowledge

The selection of kiln furniture materials is critical to production efficiency and product quality in high-temperature heat treatment processes ranging from 1000ºC to 1300ºC. This article provides an in-depth analysis of cordierite kiln furniture, highlighting its low density, porous microstructure, excellent thermal shock resistance, and exceptionally low creep rate. Through data-backed performance comparisons and practical case studies, it offers guidance for manufacturers aiming to enhance process stability and achieve cost-effective material solutions. The insights serve as a professional reference for engineers and procurement specialists involved in material optimization.

Optimizing Kiln Furniture Material Selection for 1000–1300ºC High-Temperature Processes

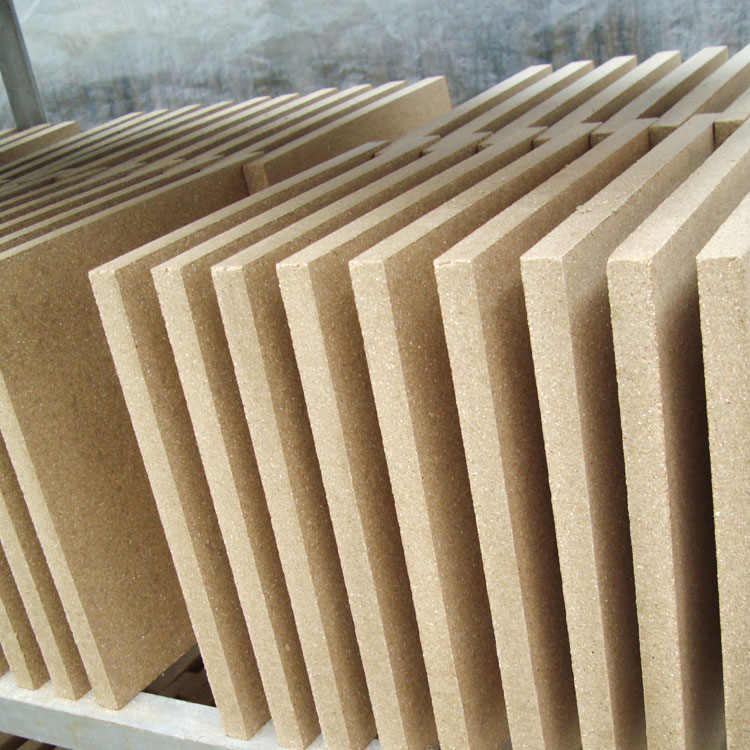

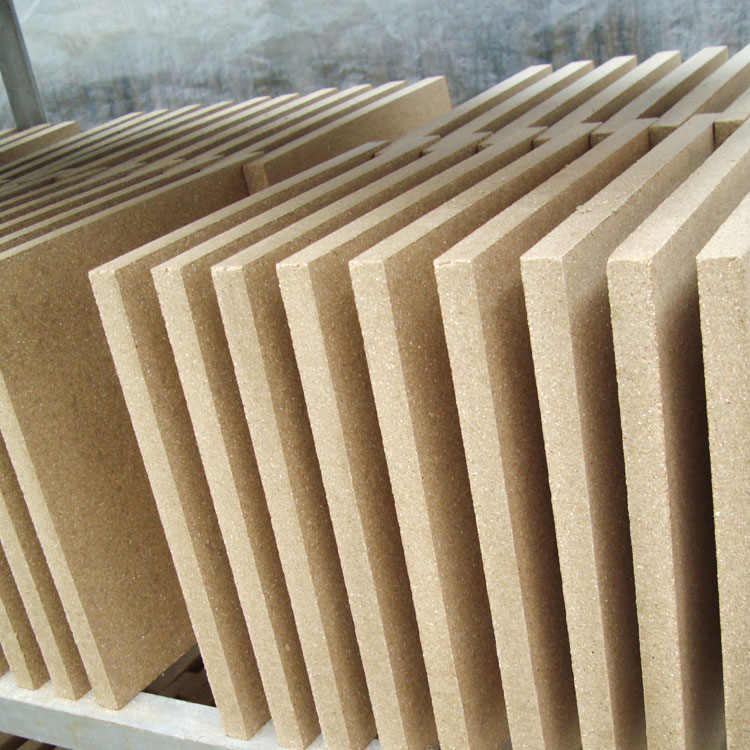

In the realm of high-temperature thermal processing, where operating temperatures range between 1000ºC and 1300ºC, the choice of kiln furniture materials plays a critical role in ensuring process stability, product integrity, and cost efficiency. Selecting materials that offer superior thermal performance, mechanical strength, and longevity can markedly reduce downtime and maintenance costs, while improving throughput. Among various candidates, cordierite (vermiculite)-based kiln furniture emerges as a leading solution, combining unique physical and chemical properties that address the demanding challenges faced by manufacturers worldwide.

Key Performance Advantages of Cordierite Kiln Furniture

Cordierite, known for its exceptional thermal stability, features a low bulk density typically around 2.3 g/cm³ and a highly porous internal structure, resulting in reduced heat capacity and enhanced insulation capability. These characteristics yield notable benefits:

- Low Thermal Mass: Speeds up heating and cooling cycles, increasing production efficiency.

- Excellent Thermal Shock Resistance: With thermal shock resistance exceeding 15 cycles at abrupt temperature changes, mesaintaining structural integrity during rapid cooling or heating.

- Minimal Creep Deformation: Cordierite exhibits a creep rate as low as 0.03% strain at 1250ºC over 100 hours, ensuring dimensional stability under prolonged loading.

- Chemical Stability: Resistant to attack by kiln atmospheres including oxidizing and mildly reducing environments.

Technical Parameters Comparison

| Material |

Density (g/cm³) |

Thermal Shock Resistance (cycles) |

Creep Rate (% strain @1250ºC/100h) |

Max Operating Temp (ºC) |

| Cordierite (Vermiculite) |

~2.3 |

≥15 |

0.03% |

1350 |

| Fused Silica Brick |

2.2 |

8-10 |

0.10% |

1200 |

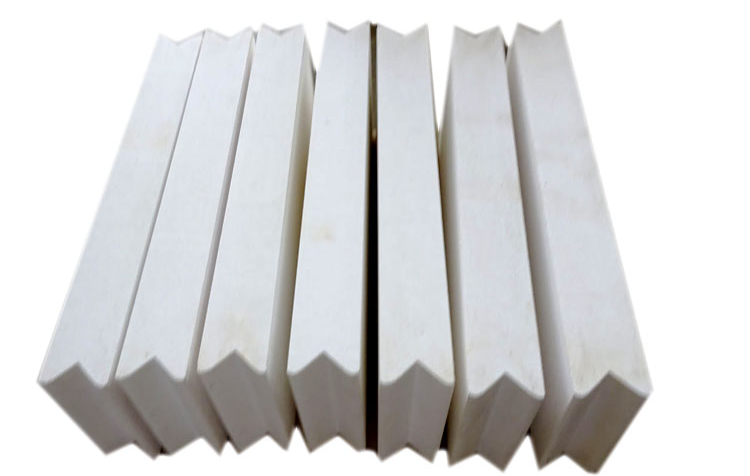

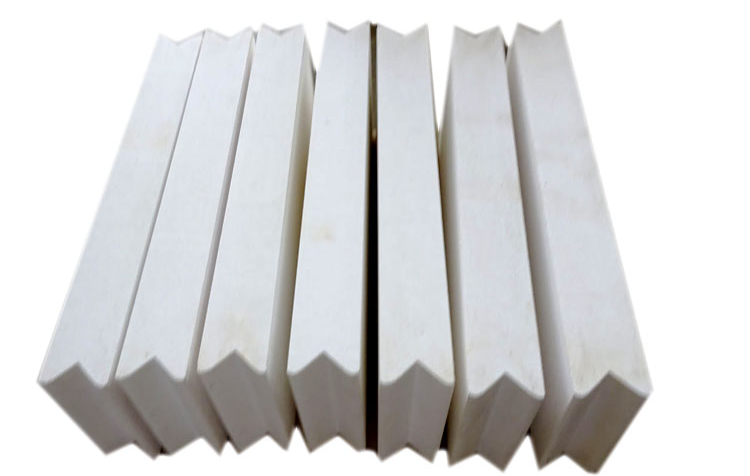

| Vermiculite Insulation Board |

0.16-0.3 |

N/A (Insulation) |

N/A |

1100 |

Real-World Application & Case Study

A leading ceramic tile manufacturer implemented cordierite kiln furniture in their tunnel kilns processing at an average temperature of 1250ºC. Prior to this upgrade, the kiln suffered frequent failures of silicon carbide setters due to thermal shock and creep deformation, leading to unplanned downtime and replacement costs every 6 months.

After transitioning to cordierite kiln furniture:

- Thermal shock failures were virtually eliminated, with equipment enduring over 18 months of continuous service without damage.

- Production cycles improved by 12%, attributed to reduced cooling/heating recovery times due to lower thermal mass.

- Overall maintenance costs dropped by 30%, enhancing the enterprise’s operational expenditure (OPEX) efficiency.

Material Selection Strategies for High-Temperature Kiln Furniture

When choosing kiln furniture materials for processes between 1000ºC and 1300ºC, manufacturers must weigh multiple factors:

- Thermal Shock Resistance: For applications involving rapid temperature fluctuations, materials like cordierite that exceed 15 thermal shock cycles provide superior reliability.

- Mechanical Stability & Creep Resistance: Prolonged exposure to high temperatures under load requires minimal deformation to maintain product geometry consistency.

- Thermal Conductivity & Heat Capacity: Lower density and porosity facilitate faster heating/cooling, enhancing productivity.

- Compatibility with Kiln Atmosphere: Resistance to chemicals and oxidation extends material lifespan.

- Lifecycle Cost Analysis: Considering both upfront investment and long-term operational savings ensures optimized procurement decisions.

Based on these considerations, cordierite kiln furniture stands out as a cost-effective and technically sound choice to enhance kiln performance and reduce lifecycle costs.

Concluding Insights

In the competitive landscape of high-temperature processing, optimizing kiln furniture materials is pivotal for production efficiency and cost control. Cordierite-based kiln furniture delivers an ideal combination of low density, exceptional thermal shock resistance, and minimal creep, enabling manufacturers to sustain stable operations and improve throughput. Supported by rigorous data and proven industrial applications, it offers a scalable solution for businesses aiming to enhance high-temperature process reliability.

Ready to elevate your thermal process with advanced kiln furniture solutions? Contact our technical specialists today for tailored advice and high-performance materials that maximize your operational ROI.