In the demanding conditions of high-temperature chemical reactors, selecting refractory materials with optimal thermal stability and corrosion resistance is fundamental to ensuring operational efficiency and longevity. The refractory magnesia-chrome bricks produced by Zhengzhou Tianyang Refractory Materials Co., Ltd. exemplify this principle by leveraging an advanced silicate bonding mechanism to elevate performance under thermal shock and corrosive environments.

Magnesia-chrome bricks primarily consist of periclase (MgO) and chromite (FeCr₂O₄) phases. The innovative approach used involves introducing silicate bonding agents during the sintering process, which effectively creates a robust vitreous phase. This vitreous silicate network acts as a binder between crystalline grains, significantly enhancing the bricks’ resistance to crack propagation and chemical degradation.

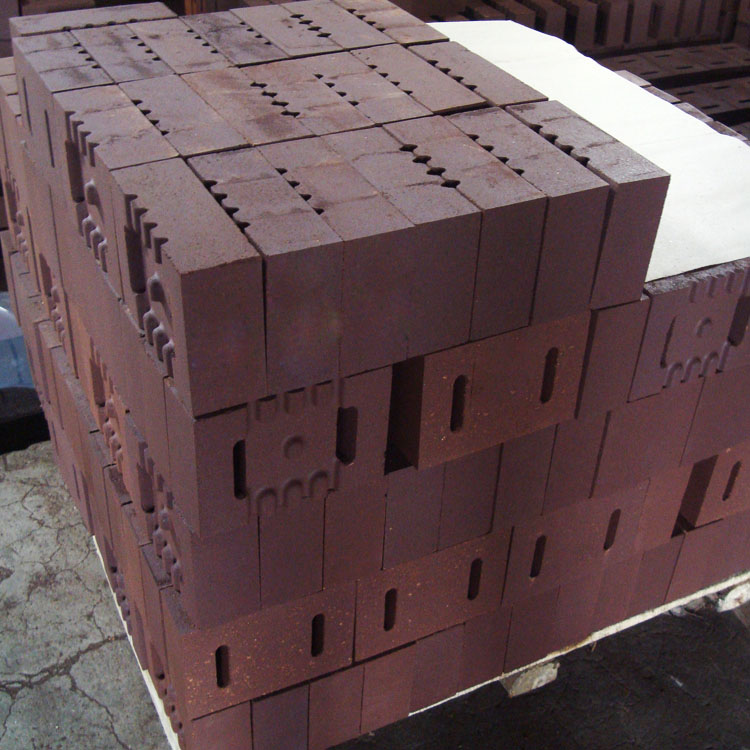

The specialized sintering techniques achieve dense microstructures with limited porosity—typically less than 3%—which are critical for minimizing corrosive element penetration and prolonging material life span under cyclic temperature variations up to 1600°C.

The silicate bonding mechanism forms a semi-amorphous matrix enveloping the MgO and Cr₂O₃ grains, which absorbs and redistributes thermal stresses arising from rapid temperature fluctuations. This significantly reduces the risk of cracking, a common failure mode for refractory bricks in environments with sudden heating and cooling cycles.

Moreover, this silicate matrix serves as a chemically inert barrier that resists infiltration by aggressive slags and gases, thus enhancing the brick’s chemical inertness. Data from standardized hot corrosion tests show a reduction in mass loss by up to 30% compared to conventional magnesia-chrome bricks without silicate bonding.

Chemical reactors operate under extreme environments characterized by abrupt thermal shocks and exposure to corrosive chemicals such as sulfur-containing gases and alkali metal slags. The application of silicate-bonded magnesia-chrome bricks in linings has demonstrated superior longevity and operational safety in industrial use cases.

Selection criteria focus on optimizing brick thickness, bonding mortar compatibility, and precise installation to maximize the brick’s intrinsic properties. Adopting rigorous installation standards, including preheating and controlled cooling procedures, is essential to fully capitalize on the material advantages provided by the silicate bonding technology.

Thermal shock resistance was quantitatively evaluated using the ASTM C1100 standard method, with bricks subjected to sudden temperature changes between ambient and 1400°C. Results consistently indicate that silicate-bonded magnesia-chrome bricks maintain structural integrity for over 150 rapid cycles before visible microcracking occurs.

The graph below depicts the correlation between residual strength and the number of thermal shock cycles, highlighting a markedly slower degradation curve compared to bricks without silicate bonding.

Correct installation maximizes refractory lifespan. Key guidelines include:

These practices ensure that the inherent benefits of silicate bonding—such as enhanced crack resistance and corrosion inhibition—are fully realized in service.

Q: How does silicate bonding compare to traditional cement bonding in magnesia-chrome bricks?

A: Silicate bonding forms a more chemically inert and thermally stable vitreous phase, reducing microcrack formation and aggressively blocking corrosive slag penetration—advantages that traditional cement bonds typically do not offer.

Q: What are the key indicators that a silicate-bonded magnesia-chrome brick requires maintenance or replacement?

A: Indicators include visible surface cracks, spalling, decreased density, or weight loss exceeding 1.5% yearly in chemical reactor environments.