Composite corundum-mullite trays have become indispensable components in the sintering process of magnetic materials due to their exceptional high-temperature stability and resistance to metal contamination. However, one persistent challenge in their application is thermal stress-induced cracking, which undermines tray longevity and ultimately affects product quality and furnace efficiency. This tutorial delves into the fundamental causes of such thermal stress cracking and presents targeted solutions grounded in process optimization and material engineering.

Thermal stress arises from uneven temperature gradients during heating and cooling cycles. For composite corundum-mullite trays, the mismatch in thermal expansion coefficients between corundum (Al2O3) and mullite (3Al2O3·2SiO2) phases generates internal strains. Under typical magnetic material sintering conditions—often reaching temperatures above 1600°C—these stresses become critical. According to [Materials Science Journal, Vol. 42, 2020], the average coefficient of thermal expansion (CTE) difference between corundum (~8.1×10-6/K) and mullite (~5.6×10-6/K) can induce tensile stresses upwards of 15 MPa during rapid thermal ramps, exceeding the fracture toughness threshold of about 10-12 MPa·m0.5.

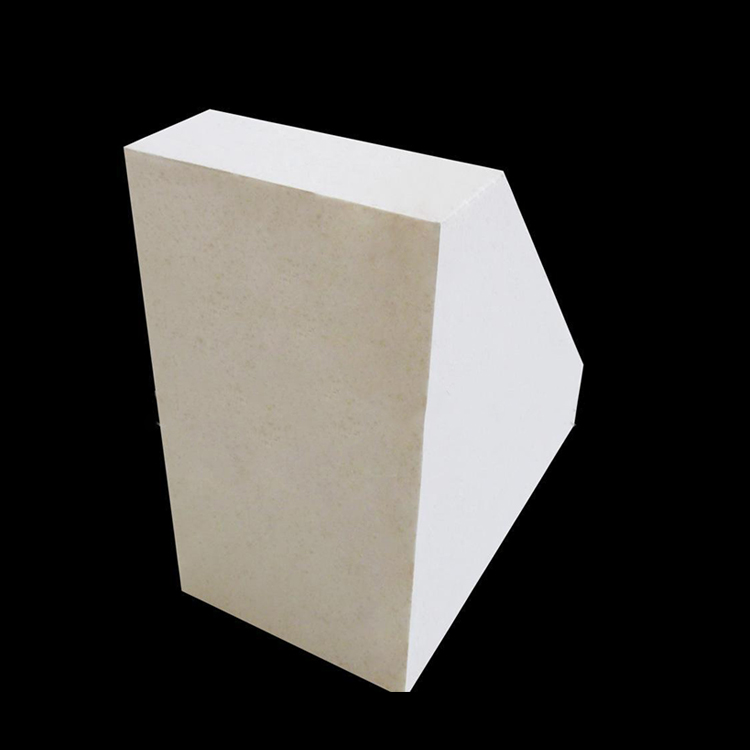

Such thermal stress cracking manifests as fissures and spalls primarily on tray surfaces and edges, impairing mechanical strength and increasing susceptibility to metal contamination and oxidation.

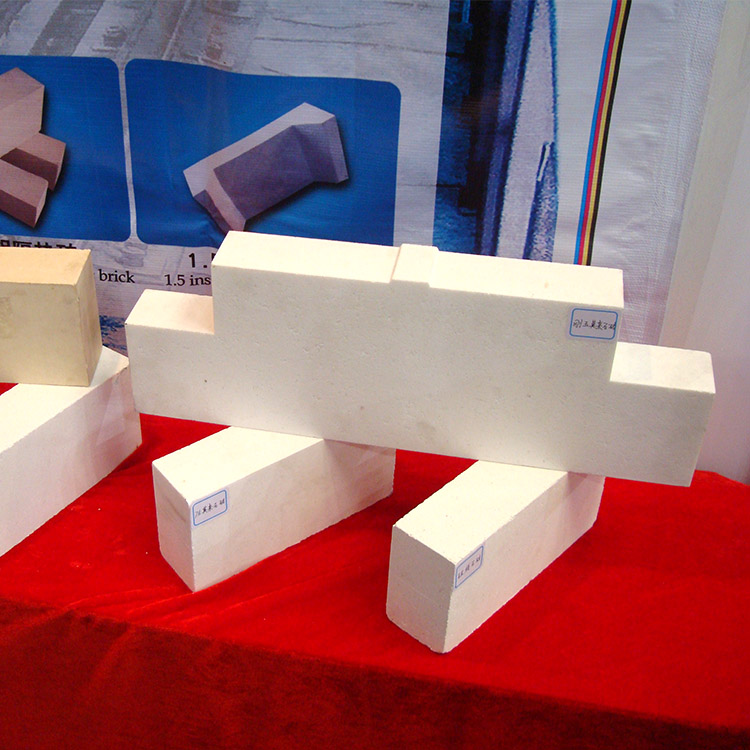

One of the most effective approaches to mitigate thermal stress is optimizing the corundum-to-mullite ratio within the tray microstructure. Research indicates that a balanced composite—typically in the range of 60–70% corundum to 30–40% mullite by weight—provides a trade-off between mechanical robustness and thermal compatibility. Additionally, refining particle size distribution and homogeneous phase dispersion reduces localized stress concentrations.

Incorporating secondary phases such as trace amounts (≤5%) of zirconia (ZrO2) can enhance toughness by promoting crack deflection. However, care must be taken to avoid excessive additions that could compromise high-temperature corrosion resistance in reducing atmospheres common in magnetic material sintering.

The sintering furnace profile plays a critical role in thermal stress formation. Industry best practices recommend controlled heating and cooling rates, typically not exceeding 3°C/min during critical temperature transitions (e.g., 800–1200°C), thereby minimizing thermal gradients. Dwelling time adjustments at intermediate soak points can also facilitate stress relaxation within the tray materials.

Furthermore, atmosphere control is paramount. High-temperature reducing environments typical in magnetic material sintering often exacerbate surface oxidation and metallic contamination. Utilizing gas mixtures with carefully balanced oxygen partial pressure can help maintain tray surface integrity. Protective coatings or surface treatments, such as high-purity alumina layers applied by sol-gel methods, have shown promise in shielding trays from metal ingress.

A leading manufacturer faced recurring tray failures characterized by edge cracking and surface oxidation during mass production of ferrite magnetic cores. By implementing a composite design with 65% corundum and 35% mullite, alongside strict furnace ramping limits of 2°C/min, cracking incidents were reduced by 75% over six months. Additionally, introducing a thin alumina coating layer further extended tray service life by 40%.

Analysis via scanning electron microscopy (SEM) confirmed the diminished presence of micro-fissures, correlating with improved sintered product consistency and reduced downtime for tray replacement.

| Parameter | Recommended Range/Value | Impact on Thermal Stress |

|---|---|---|

| Corundum Content | 60–70 wt% | Balances mechanical strength and thermal expansion |

| Heating/Cooling Rate | ≤3°C/min | Reduces thermal gradients and stress buildup |

| Addition of Zirconia | ≤5 wt% | Improves fracture toughness; excessive amounts detrimental |

| Atmosphere Control | Low oxygen partial pressure, protective coatings | Prevents oxidation and metal contamination |

For technical teams seeking to elevate their sintering tray reliability and optimize magnetic material production, fine-tuning these parameters is indispensable. Leveraging proven material formulations combined with careful furnace protocol adjustment facilitates significant reductions in thermal stress cracking.

Discover Expert Solutions to Enhance Your Sintering Tray Performance Today