Sanitary ware manufacturers frequently face the frustrating issue of product warping post-firing. Contrary to popular belief, this problem often stems not from the raw body but rather from inadequate thermal stability of the kiln supports, particularly the trays or setters. Selecting the right tray material and managing its aging process can be critical in minimizing deformation and maximizing kiln yield.

In high-temperature kiln operations, especially within the 1000°C to 1400°C range, the thermal expansion behavior and mechanical strength retention of kiln trays play a decisive role. Traditional refractory bricks or standard ceramic trays often suffer from insufficient structural integrity and uneven thermal expansion, leading to uneven support and stress concentration on sanitary ware pieces during firing.

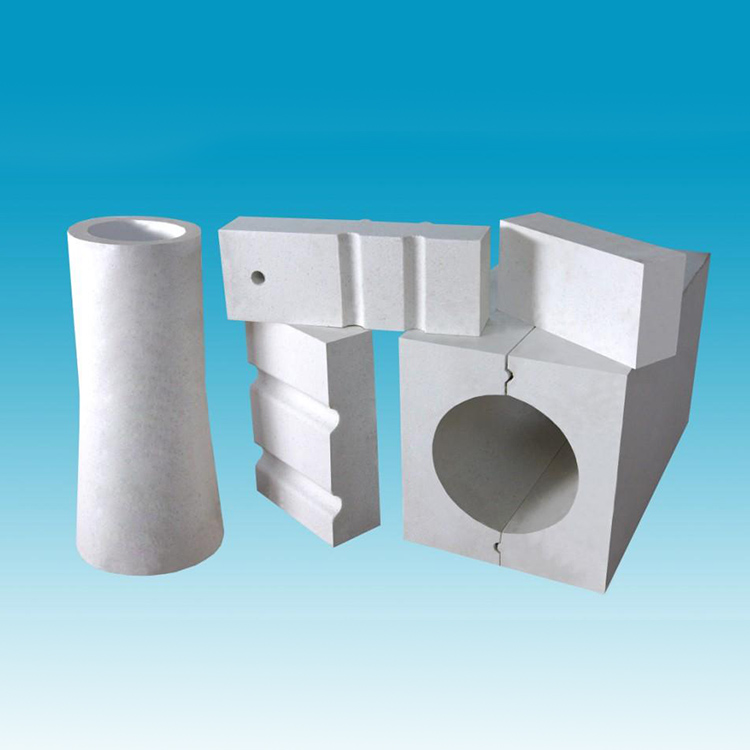

A notable alternative is the use of composite corundum-mullite trays, which exhibit superior heat resistance and maintain mechanical strength after prolonged exposure to elevated temperatures. Their lower thermal expansion coefficient and enhanced anti-bending performance ensure more uniform support, drastically reducing the likelihood of post-firing warp.

Composite corundum-mullite trays typically demonstrate a thermal expansion coefficient less than 7 × 10−6/°C between 1000°C and 1400°C, compared to over 10 × 10−6/°C for standard fireclay bricks. Furthermore, their bending strength at 1200°C remains above 35 MPa, outperforming traditional alternatives by 20–30%. This mechanical resilience underpins their ability to maintain dimensional stability during repeated kiln cycles.

The requirements for kiln supports vary across ceramic products. For example:

The varying thermal stresses in these scenarios underscore the necessity of selecting kiln supports optimized for the specific firing profile and product geometry.

"Investing in thermally stable composite trays not only reduces defective rates but also extends kiln service intervals. This strategic choice pays off through enhanced process reliability and lower overall production costs." – Dr. Laura Meyer, Ceramic Engineering Consultant

Tray degradation is a gradual process influenced by thermal cycling, chemical corrosion, and mechanical wear. Common aging indicators include:

Regular inspection combined with non-destructive testing techniques like ultrasonic flaw detection can preempt catastrophic tray failures. Matching tray structures—such as monolithic versus segmented designs—to specific kiln types (roller hearth, shuttle, tunnel) ensures mechanical compatibility and thermal endurance.

| Temperature (°C) | Thermal Expansion Coefficient (×10−6/°C) | Bending Strength (MPa) |

|---|---|---|

| 1000 | 6.5 | 42 |

| 1200 | 6.9 | 38 |

| 1400 | 7.2 | 34 |

This trend highlights the importance of designing trays with materials that minimize expansion mismatches and retain mechanical integrity, especially during peak firing stages.

The firing warpage issue can be systematically approached by:

A leading sanitary ware producer achieved a 30% reduction in post-firing warpage within six months of transitioning to composite corundum-mullite kiln trays, accompanied by a 15% increase in overall kiln throughput by minimizing unscheduled downtime.

Implementing these insights empowers kiln managers and engineers to select fitting kiln tray solutions that align with their process specifics, product geometry, and quality goals.

Enhance Your Firing Outcomes with Expert Insights — Download the Ceramic Tray Selection Whitepaper PDF or Join Our Ceramic Kiln Technology Community Today!